Enabling Materials of the Future

Based at the Centennial Campus of NC State University, The Nonwovens Institute (NWI) engages industry, government and academia to enable next-generation nonwoven solutions to mission-critical challenges.

300+ Alumni

Facilitating collaboration around fundamental research – TRL 1-3.

Knowledge Creation

100+ Companies Trained Annually

In-person, online and custom training opportunities – TRL 4-9.

Workforce Development

100+ Industry Partners Annually

World-class pilot and testing labs to support trials – TRL 3-6.

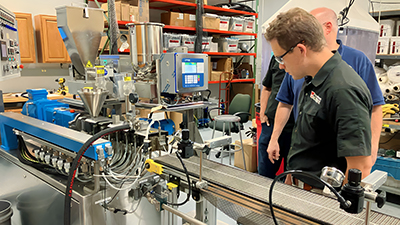

Fabrication and Testing

80+ Patents; Many Commercialized

Bringing new product ideas from concept to reality – TRL 4-7.

Problem Solving

7 Products Incubated

Scaling from the lab to commecialization – TRL 6-9.

Product Incubation

Student Spotlight: Anicah Smith-O’Brien, Biodegradability and Functional Properties of Biopolymers

“The Institute will continuously strive to be a global leader in research, education and outreach for the nonwovens and affiliated industries.”

NWI Industrial Advisory Board

Member Profile:

Math2Market

Follow NWI

Join our mailing list to keep up-to-date with everything happening at NWI!