Meltblown Lab

The Nonwovens Institute at North Carolina State University offers state-of-the-art technology and deep expertise in meltblown nonwoven applications.

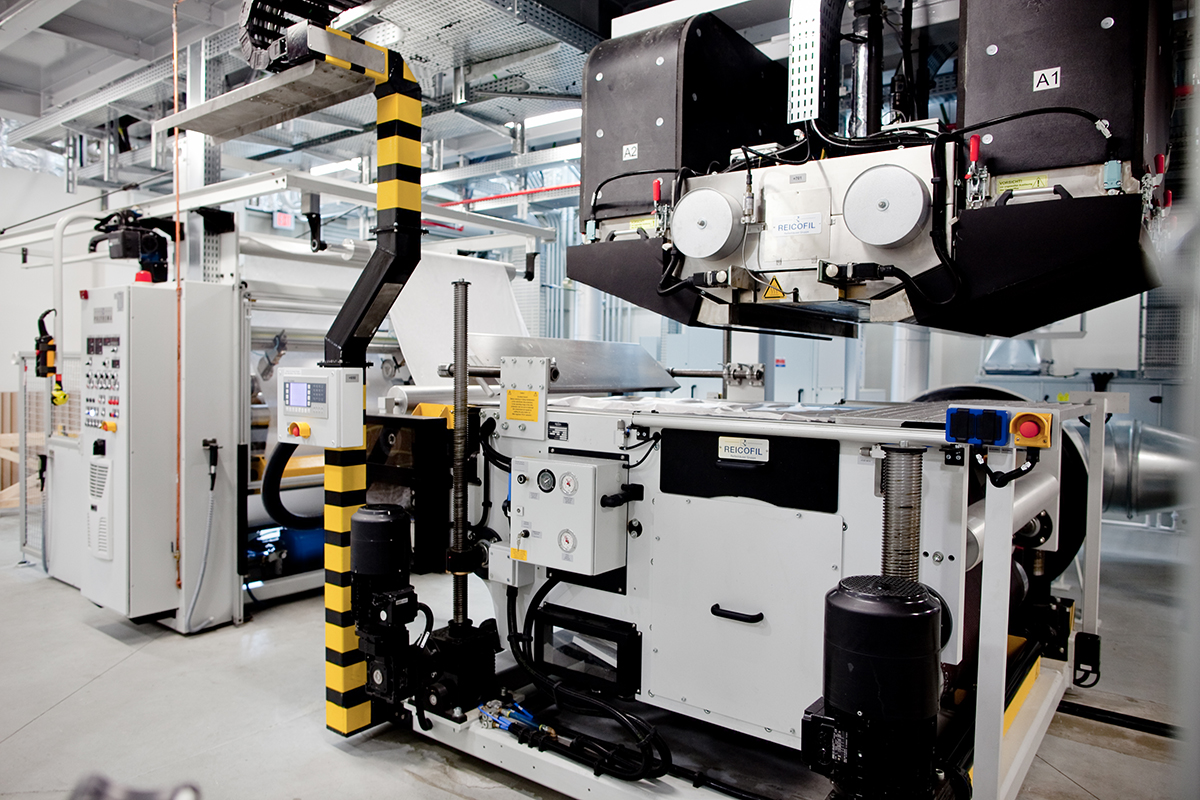

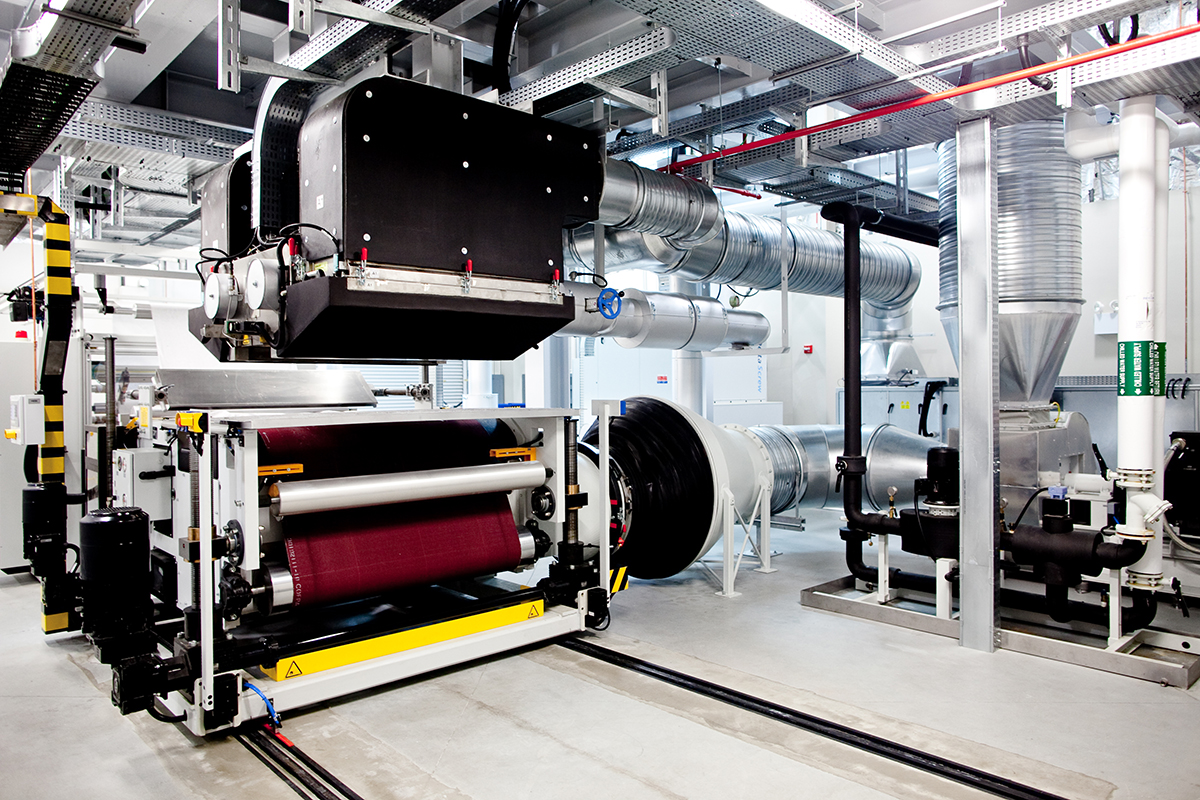

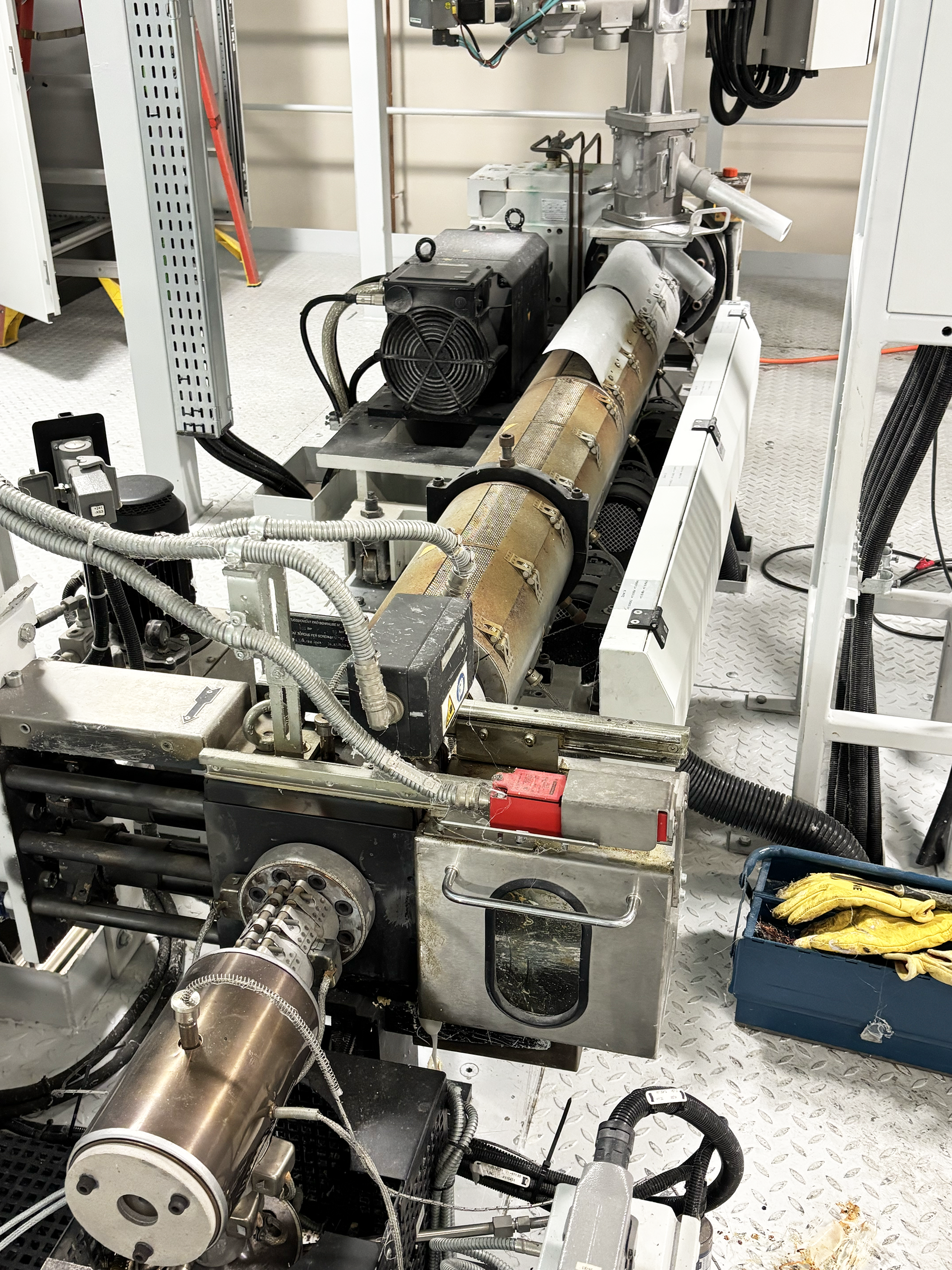

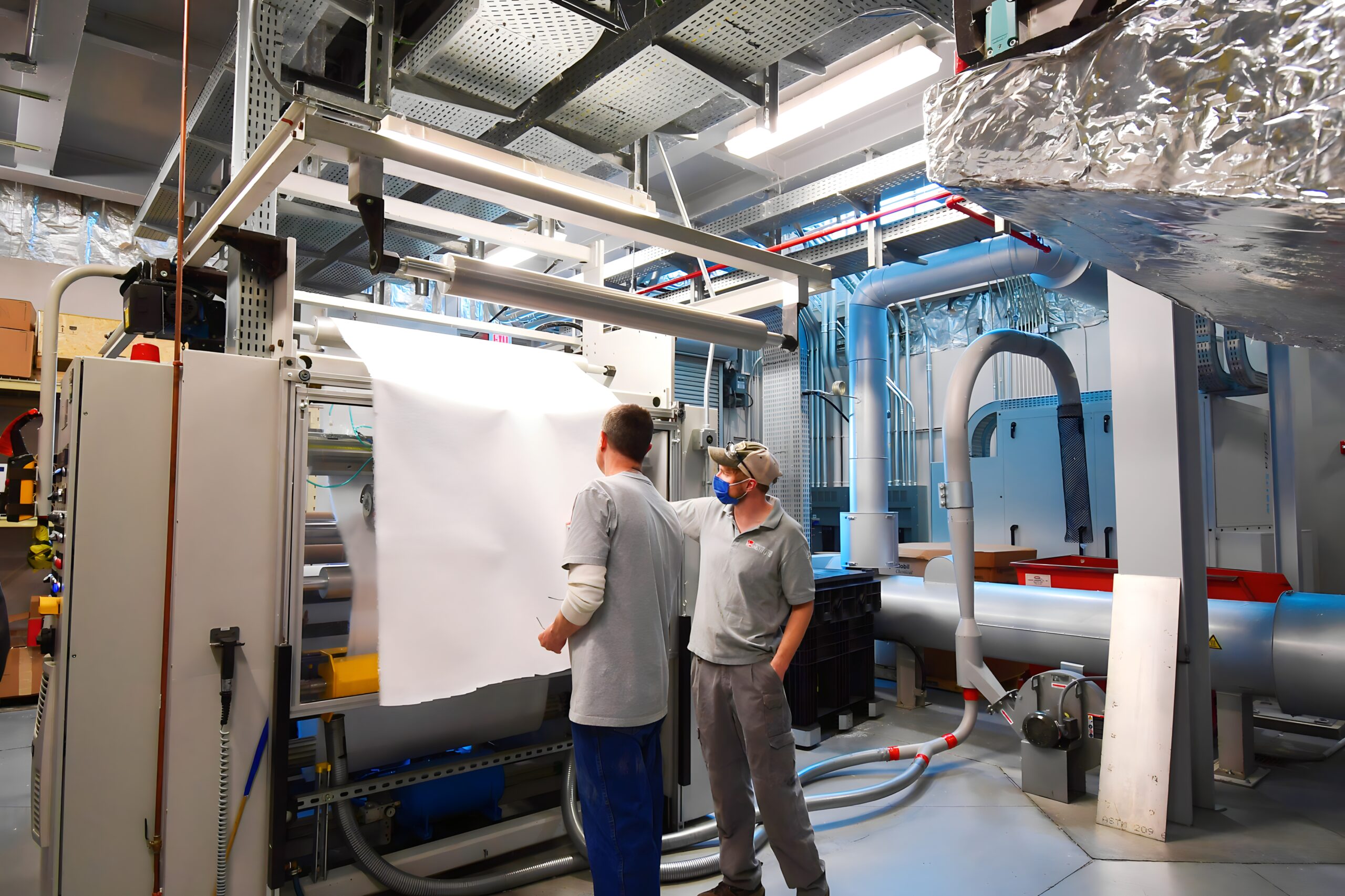

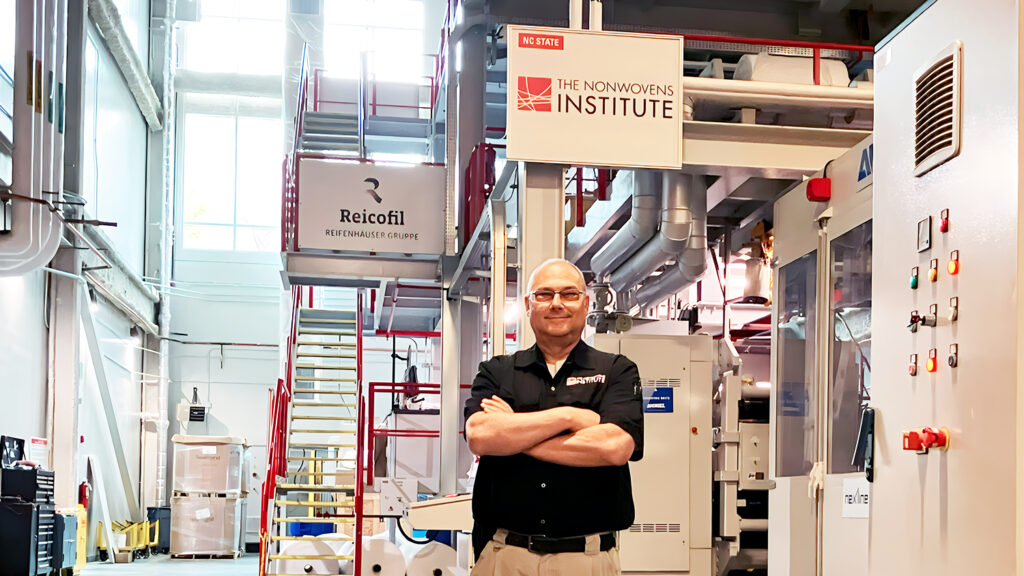

The Nonwovens Institute features a 1.2-meter wide Reifenhäuser Reicofil pilot line with recently updated software and control systems. Along with NWI’s many years of experience in developing meltblown nonwoven applications, this stand-alone machine provides the ability to test a wide range of polymers, including polyolefins, polyamides, polyesters, elastomers, PLA and many others. Importantly, this meltblown system includes in-line electrostatic charging capability (corona).

NWI’s facilities also include laboratories dedicated to polymer characterization, fiber extrusion and lab scale meltblown. Our Analytical & Physical Testing and Filtration Media labs offer the ability to analyze and evaluate material performance according to many industry-specific standard test methods, including, notably, ISO-17025 for filter media.

Meet the Lab Manager:

Angelo Corino

If you have questions about running trials at NWI, please email us at nonwovens@ncsu.edu.

If you wish to use the pilot equipment or have some testing done, you will need to have a Fabrication and Testing Services Agreement in place.

Meltblown Lab Documentation

Photo Gallery

NWI Meltblown Pilot Lab

Equipment Specifications

| Reicofil 4 Meltblown Line | |||

|---|---|---|---|

| No. of Beam | 1 | Width (m) | 1.2 |

| Line speed (m/min) | 1-100 | Dosing units for additives (%) | 1 @ 0.5-3; |

| Die to Collector distance (mm) | 150 to 500 | Dies (HPI); Capillary Size (microns) | 20 | 600 25 Mixed | 600; 300 35 | 400 45 | 300 60 | 300 60 | 250 75 | 180 6-row Biax | 500 |

| Collector table angle | 20 | Conveyor belt | Polyester woven |

| Extruder size (mm); L/D | 70; 30:1 | Winder (Type); Core Size (inches) | Automatic surface driven; 3” |

| Max die temp (C) | 310 | Tension control (N) | 10 to 160 |

| Max air temp (C) | 350 | Max air volume (m3/hr/m) | 2,000 |

| Electrostatic charging capability (corona) | 4 charging bars, up to 50 kV per bar. | ||

If you have questions about running trials at NWI, please email us at nonwovens@ncsu.edu.