Staple Nonwovens Lab

The Nonwovens Institute at North Carolina State University offers state-of-the-art technology and deep expertise in staple fiber-based nonwoven applications.

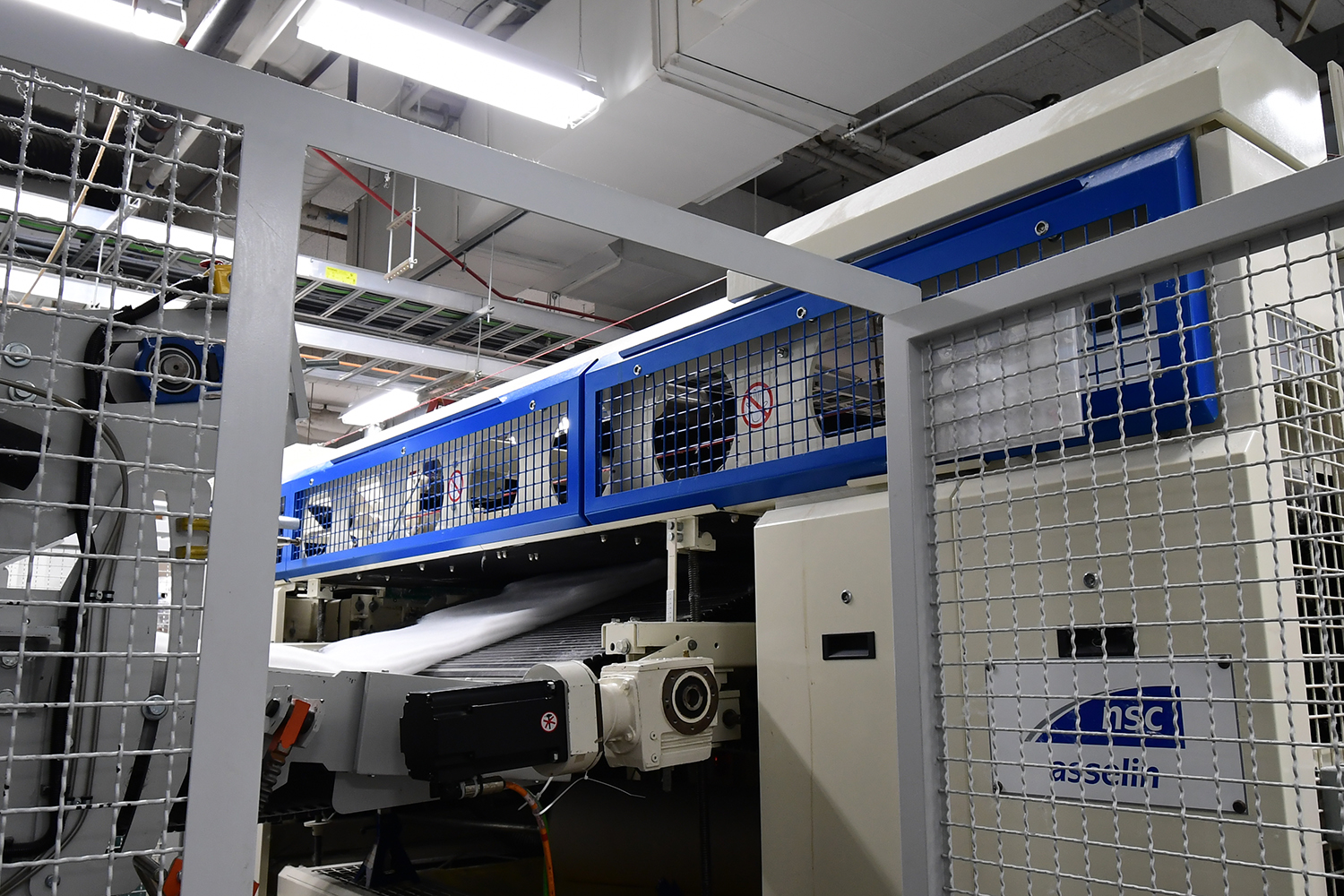

The Nonwovens Institute’s many years of in-house knowledge in staple nonwovens are supported by the Staple Nonwovens Pilot Lab, which is equipped with Trützschler feeding equipment and extensive opening systems that allow for blending of various types of fibers and composite formations.

The facility is outfitted with two separate feeding systems from the opening equipment, which can be used independently to feed the card or a Scanfeed system for high-loft substrates.

This facility also includes a 1-meter wide Trützschler High-Speed Nonwoven EWK 413 Card, which processes fibers from 0.9 to 20 denier with basis weights ranging from 20 to 100 g/m2 direct lay.

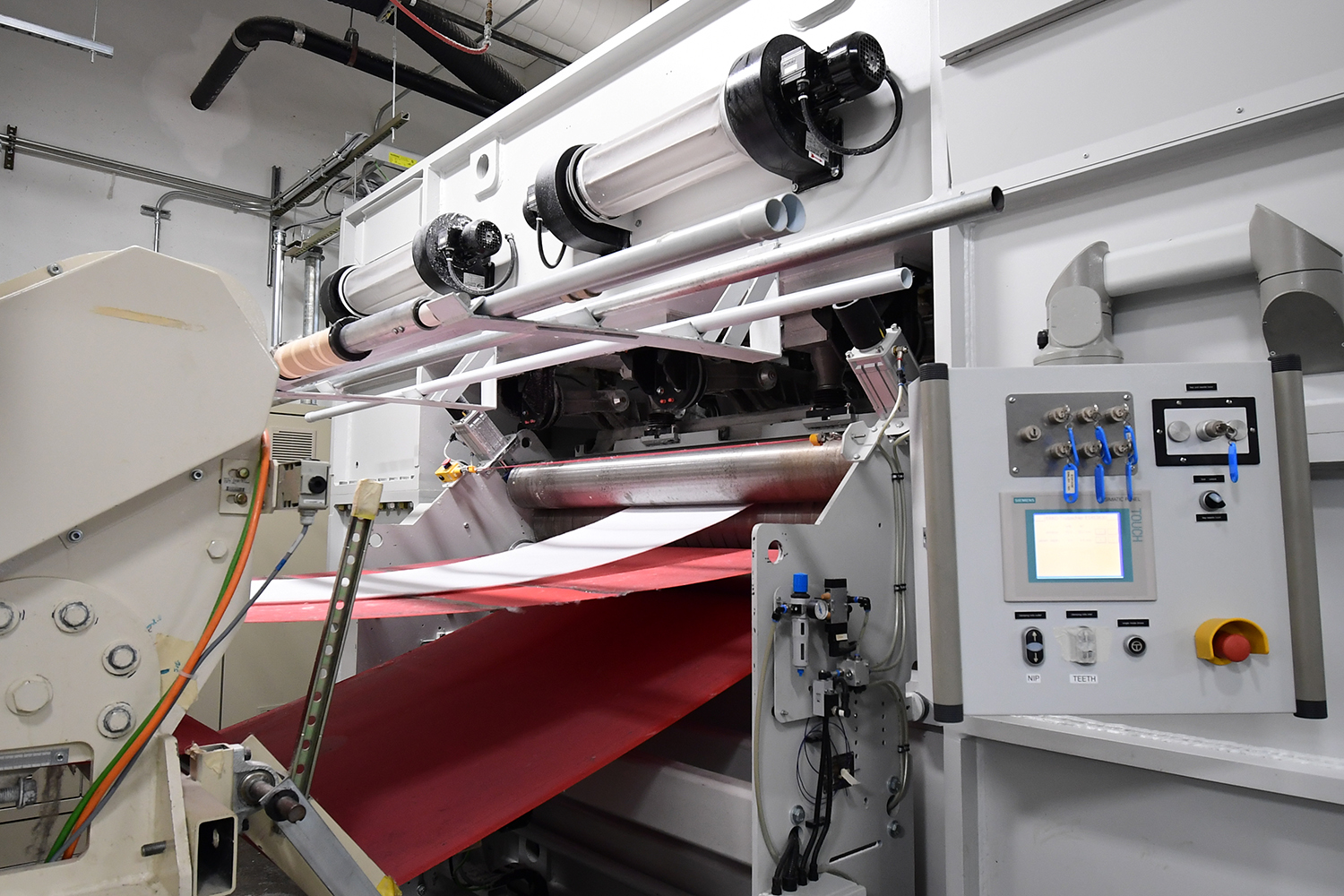

An Andritz Profile 415-FD Crosslapper provides automatic batt width adjustment, automatic overlap control and adjustment, and full control over the number of layers, with automatic computation of the necessary delivery speed on the floor apron. This equipment is capable of producing very heavy batts. The Profile technology, as the name implies, can shape the outgoing material to optimize weight distribution from center to side of the fabric.

The Scanfeed is situated behind the Crosslapper to allow for manufacturing of high-loft webs. The batt can be fed directly to the needle-punch equipment or used to form a layered composite with the lapped web from the card and the Crosslapper.

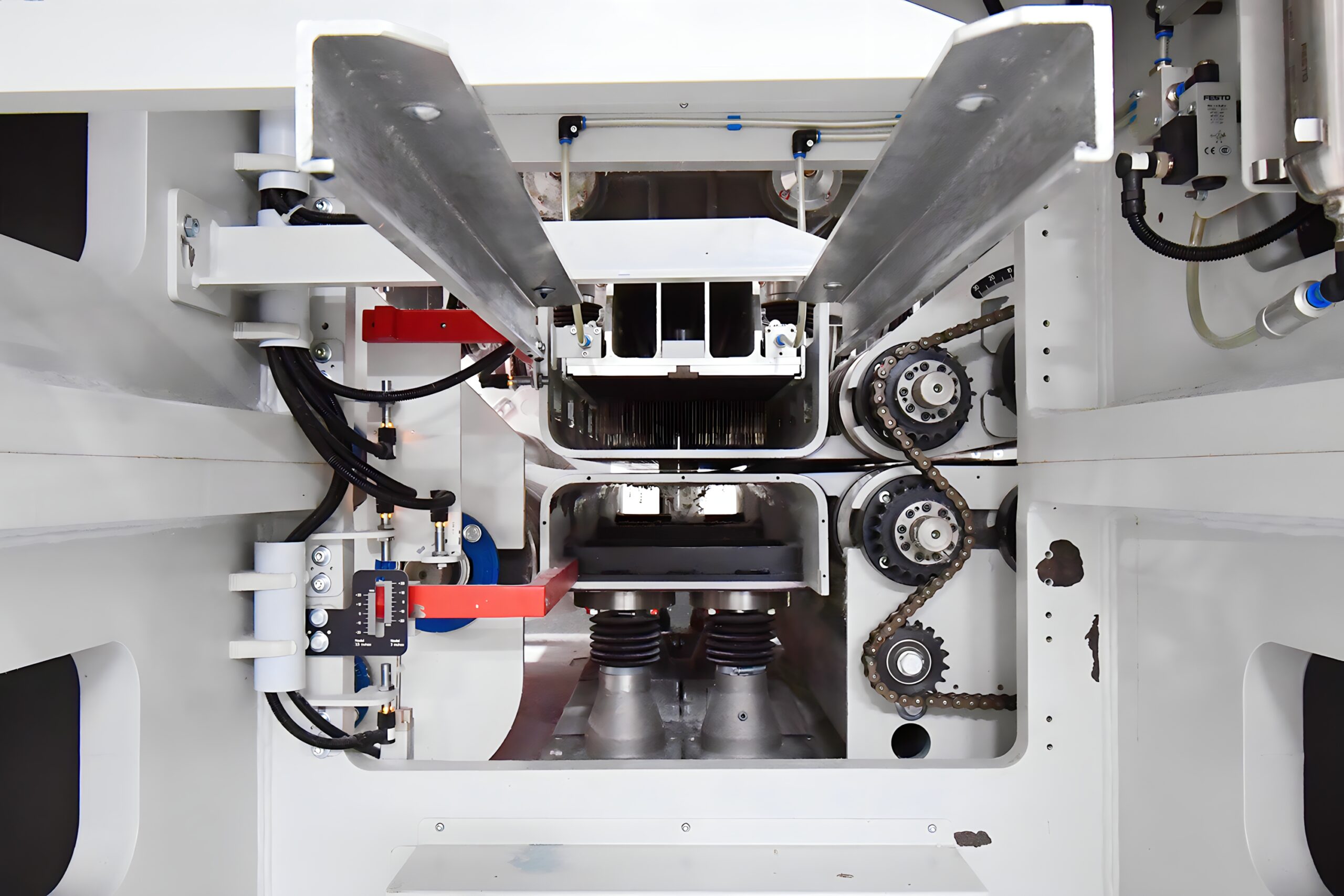

The facility includes two bonding technologies – needle-punch and through-air bonding. The pre-needler is a Trützschler single-board needle loom ENL followed by an Andrtiz A.50-RL needle loom, DF-4 version with 4-boards; two up, two down stroke. The needle loom has a highly flexible needle pattern and results are repeatable with industrial-scale machines. For through-air bonding, the lab is outfitted with a Fleissner flat 4-zone impingement/through-air oven.

Additional bonding technologies such as calendering or hydroentangling are available in NWI’s other pilot facilities.

If you have questions about running trials at NWI, please email us at nonwovens@ncsu.edu.

If you wish to use the pilot equipment or have some testing done, you will need to have a Fabrication & Testing Agreement in place.

For each pilot equipment, we provide the following guidelines and templates. The guidelines contain the specification of the relevant machinery as well as the cost of using the various options. The trial plan provides a starting point outline of important test configuration options and choices, as well as test matrix design to ensure needs are met.

Photo Gallery

NWI Staple Nonwovens Lab

Equipment Specifications

| Trützschler Nonwovens EWK 413 Card | |||

|---|---|---|---|

| No. of Beam | 1.0 | Width (m) | 1.0 |

| Line speed (m/min) | 1.0 to 100 (Direct Lay) | Fiber (Denier) | 0.9 to 20 |

| Web Weight (g/m2) | 20 to 100 direct lay random web | Fiber Length (mm) | 20 to 76 |

| Trützschler Scanfeed | |||

|---|---|---|---|

| Web Width (m) | 1.0 | Fiber (Denier) | 0.5 to 20 |

| Max Throughput (Kg/h/m) | 400 | Fiber Length (mm) | 50 to 100 |

| Web Weight (g/m2) | 300 to 1500 | ||

| Andritz Profile 415-FD Crosslapper (née Asselin) | |||

|---|---|---|---|

| Delivery Width (m) | 1.0 | No. of Folds | 2.0 to 50 |

| Max Input speed (m/min) | 100 | Stroke Freq (RPM) | 1200 |

| Trützschler Needle Loom ENL | |||

|---|---|---|---|

| No. of Board | 1.0 | Needles/m | Up to 5000 |

| Line speed (m/min) | 20 | Stroke Freq (RPM) | 1200 |

| Andritz A.50-RL Needle Loom (née Asselin) | |||

|---|---|---|---|

| No. of Board | 4 – configurations: 2 up or 2 down; 1 up and/or 1 down | Needles/m | Up to 5000 |

| Line speed (m/min) | 30 | Stroke Freq (RPM) | 1200 |

| Max Width (m) | 1.4 | ||

| Fleissner Oven | |||

|---|---|---|---|

| Line speed (m/min) | 1.0 to 15 | Max Temp (C) | 230 |

| Max Width (m) | 1.2 | ||

| Parkinson Winder | |

|---|---|

| Line speed (m/min) | 1.0 to 20 |

If you have questions about running trials at NWI, please email us at nonwovens@ncsu.edu.