The Nonwovens Institute (NWI) is proud to recognize Vinod Balakrishnan, Sophie Nunno-Gorbachev, and Pallav Jani – three Ph.D. students who participated in the Institute’s fundamental nonwovens research program and will graduate in May.

“NWI offers our sincere congratulations to these three fine researchers, who are now entering the next phase of their journey in the world of material science. We wish them all the best and look forward to watching them grow as they move along their career paths in the years to come,” said Behnam Pourdeyhimi, Ph.D., NWI’s executive director.

Vinod Balakrishnan, Ph.D., Mechanical and Industrial Engineering, University of Illinois Chicago

“Probability of Fiber-Fiber Touching and Roping in Meltblowing at Smaller Inter-nozzle Distances”

Vinod Balakrishnan will defend his Mechanical and Industrial Engineering Ph.D. dissertation, titled “Numerical and Experimental Study of Roping in Nonwoven Formation Processes,” later this month and is expected to graduate from the University of Illinois Chicago in May. Vinod’s industry-identified NWI research project focused on predicting the effect of the inter-nozzle distance at the nosepiece on the probability of fiber-fiber touching in flight – especially for small distances – as well as the effect of the inter-nozzle distance on the laydown structure in solution and meltblown systems.

Solution and meltblowing is used in such applications as electronics, filtration, tissue engineering, in-situ biomaterial fabrication, and rapid scaffold generation. Nanofibers with smart properties are becoming more and more important due to their potential applications, such as displays and wearable electronic textiles. Industry utilizes high-density nosepieces for large-scale manufacturing and is interested in diminishing the inter-die distances as much as possible. The question is: what is the limit where severe roping (a potential result of fiber-fiber touching) could set in? Vinod’s research focused on optimizing production processes to achieve heightened throughput rates, while maintaining the requisite quality standards of the final product.

Prior to pursuing his Ph.D. in Mechanical and Industrial Engineering at the University of Illinois Chicago, Vinod earned his master’s degree in Aeronautical Engineering from Hindustan University, Chennai, India, as well as a bachelor’s degree in Mechanical Engineering from the University of Kerala in Trivandrum, India. Vinod also served as an assistant professor, research associate and lecturer for various universities in India.

Vinod presented his research at NWI’s semi-annual Industrial Advisory Board (IAB) meetings from November 2019 to November 2022. He has also published his research in the Journal of Applied Physics (2022) and Journal of Applied Polymer Science (2023), with an additional publication currently being prepared for the Journal of Applied Physics in 2024.

“My journey through this Ph.D. program has been a testament to the power of collaboration and mentorship. Under the guidance of Dr. Behnam Pourdeyhimi and Dr. Alexander Yarin, I have not only flourished academically, but also developed a deep sense of gratitude for the opportunities afforded to me,” said Vinod. “Engaging with The Nonwovens Institute and esteemed industry experts has broadened my perspective on real-world applications of our research. Through participation in Industrial Advisory Board presentations and interactions with industry professionals, I have cultivated a sense of fusion of academic rigor and practical relevance. My academic journey along with NWI also instilled in me a profound appreciation for the symbiotic relationship between academia and industry in tackling complex challenges.”

Vinod is actively exploring opportunities the industrial sector.

Sophie Nunno-Gorbachev, Ph.D., Textile Technology Management, NC State University

“Direct-to-Textile 3D Printing”

Sophie successfully defended her Textile Technology Management Ph.D. dissertation, titled “Material Characterization and Structure-Property Relationships for Direct-to-Textile 3D Printing,” in November 2023 and will graduate from NC State University in May. Sophie’s industry-identified NWI research project focused on developing a better understanding around the process of direct-to-textile 3D printing; investigating 3D-printed structures and prototypes; and studying the interaction between 3D-printed parts and fabric.

Current pre-production and manufacturing processes present limitations, such as complications with materials management, significant fabric waste, and slower-than-ideal manufacturing times. The implementation of additive manufacturing may allow for design specifications to be printed directly onto a fabric, reducing material waste, simplifying the sourcing process, and streamlining manufacturing.

Prior to pursuing her doctoral degree, Sophie earned her bachelor’s degree in Fashion and Textile Management from the Wilson College of Textiles at NC State. She found her passion for research through an undergraduate project to evaluate the impacts of bras on the human body with the department of Textile Apparel Technology and Management at NC State. During her Ph.D. studies, Sophie served as a research and development intern for Hanesbrands Inc.

Sophie has presented her research at Techtextil North America in Atlanta, Georgia, from May 10-12, 2023; the Research, Innovation, and Science for Engineered Fabrics (RISE®) Conference in Raleigh, North Carolina on September 27, 2022, and The IDEA® Conference in Miami, Florida, from March 28-31, 2022.

Sophie also presented her research at NWI’s IAB meetings from 2019-2023.

Sophie recently launched her own company, Fibonix Inc., a venture with the mission to provide dynamic innovative solutions for groundbreaking research and disruptive product development to companies in the apparel and textile sectors.

“The Nonwovens Institute is a place where innovation meets specialization; where highly-skilled and motivated teams of researchers, technicians, product developers, and scientists collaborate on research projects to benefit the nonwovens industry as a whole,” said Sophie. “For me, working with the NWI felt like seeing a glimpse into the sustainable materials-driven world of tomorrow.”

Pallav Jani, Ph.D., Chemical Engineering, NC State University

“Interaction Between Slip Additives and Hydrophilic Finishes in Nonwovens”

Pallav successfully defended his Chemical Engineering Ph.D. dissertation, titled “Adsorption, Friction and Reinforcement Mechanisms at Functional Polymer Interfaces,” in March and will officially graduate from NC State University in May. Pallav’s industry-identified NWI research project focused on understanding the interaction between slip additives and hydrophilic finishes in nonwovens.

Pallav examined the surface modification of spunbond nonwovens, particularly those used in hygiene products, such as diapers, incontinence pads, etc., as topsheets. These materials are often in contact with the skin and require a dual functionality of being hydrophilic to allow water transport to the adsorbent core of the product, while also imparting soft comfort perception to the user. Since most topsheets are hydrophobic polypropylene-based, different additives/coatings are used to achieve these properties. Surfactant coatings are used to impart wettability, while amphiphilic slip additives, such as erucamide, are used to reduce the friction to render a soft hand feel. When both additives exist simultaneously at the surface of the nonwoven fibers, they can either work synergistically or result in performance issues.

Prior to pursuing his doctoral degree, Pallav earned a bachelor’s degree in Oils, Oleochemicals and Surfactants Technology from the Institute of Chemical Technology in Mumbai, India, and a master’s degree in Chemical Engineering from the University of Michigan, Ann Arbor, Michigan. Pallav has also served internships with Ford Motor Company, working on friction modeling of diesel engines to enable fuel efficiency, and TE Connectivity, supporting projects related to the characterization of dry and lubricated friction, wear analyses, and the identification of failure modes for metal coating and electrical connectors.

Pallav has presented his NWI research at the Research, Innovation, and Science for Engineered Fabrics (RISE®) Conference in Raleigh, North Carolina in 2019 and 2022, and at the IDEA® Conference in 2022.

Pallav also presented his research at NWI’s IAB meetings from 2019-2023 and has been a three-time recipient of IAB presentation awards.

Pallav recently began working as a Senior Scientist at TE Connectivity in Fremont, California, focusing on sustainable polymer formulations development.

“My entire Ph.D. experience has been extremely fruitful due to the guidance, care, and research freedom afforded to me by my wonderful advisors, Dr. Saad Khan, and Dr. Lilian Hsiao,” said Pallav. “Working with the NWI and leading industry experts has helped me immensely in executing my research projects It has also given me a tremendous appreciation for industry-academic research collaborations that allow graduate students like me to contribute to solving industrial challenges. I’ve enjoyed the time I spent with NWI graduate student group as well, developing a sense of community outside our research groups and always learning new and exciting things in our meetings.”

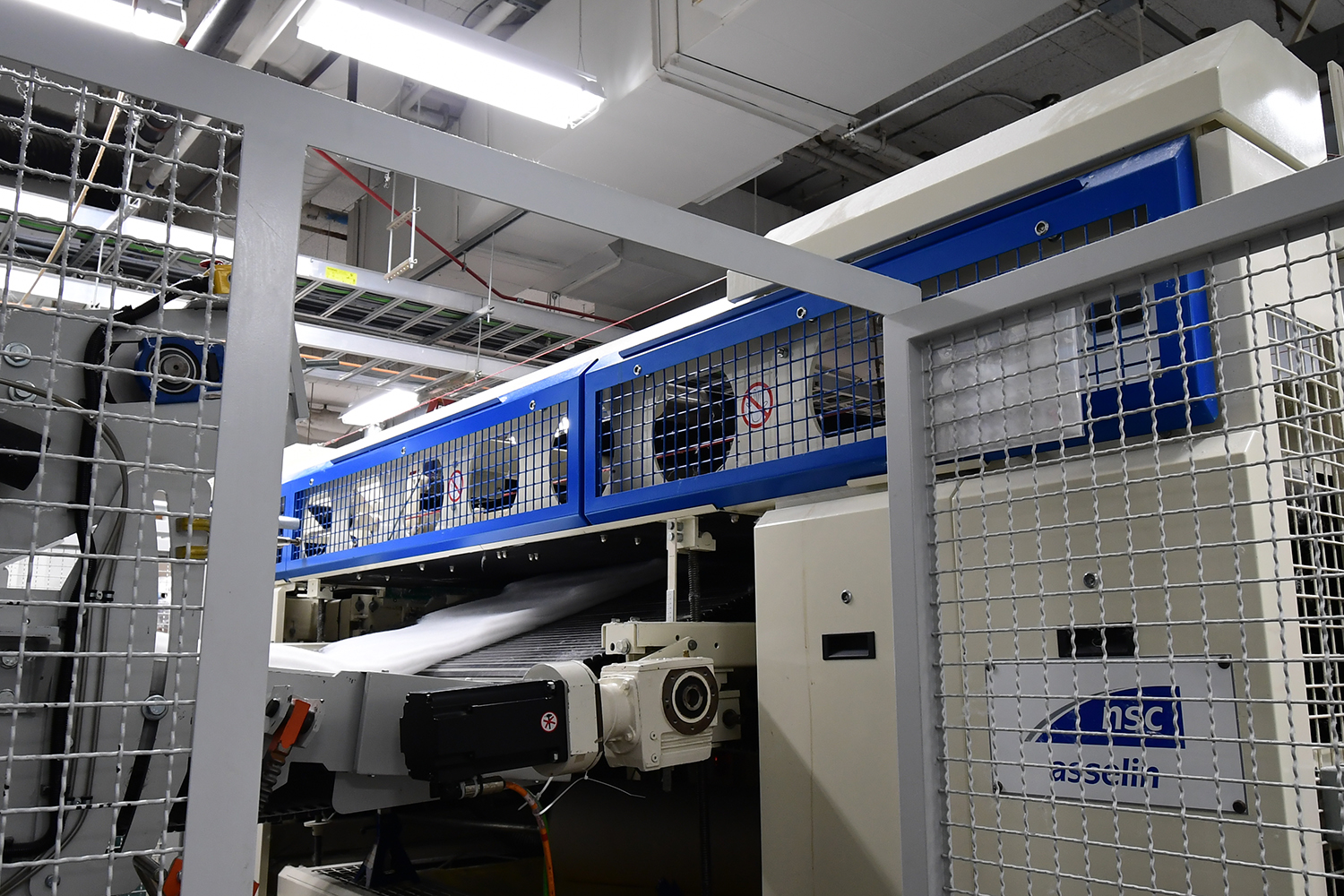

NWI offers graduate students the opportunity to participate in fundamental research in areas that address the pressing challenges in nonwovens applications and technology. Student researchers working through the NWI program benefit from a diverse range of perspectives, working hand-in-hand with subject matter experts from academia and industry.

Students engage with NWI by partnering with faculty from the degree program of their choice. Research projects are developed by faculty and selected by NWI member companies. Students are selected based on their academic performance and capability within the industry-selected research programs. Proposal selection is a competitive process, and NWI does support the submission and selection of research proposals from faculty at other universities.

NWI supports students from a number of academic programs including Fiber and Polymer Science, Chemical and Biomolecular Engineering, Mechanical and Aerospace Engineering, Materials Science and Engineering, Forest Biomaterials, and Biomedical Engineering, as well as students in various engineering programs at partner institutions.

Students who are engaged in an NWI-supported research project will graduate with a degree in the discipline to which they are admitted, but their research will be focused on a topic of relevance to nonwovens.

- Categories: