[2-Minute Tutorial] Carded Nonwovens Technology

The following tutorial covers a segment of material from the Carded Nonwovens Technology Short Course, which will be presented Apr. 1-3 at The Nonwovens Institute (NWI).

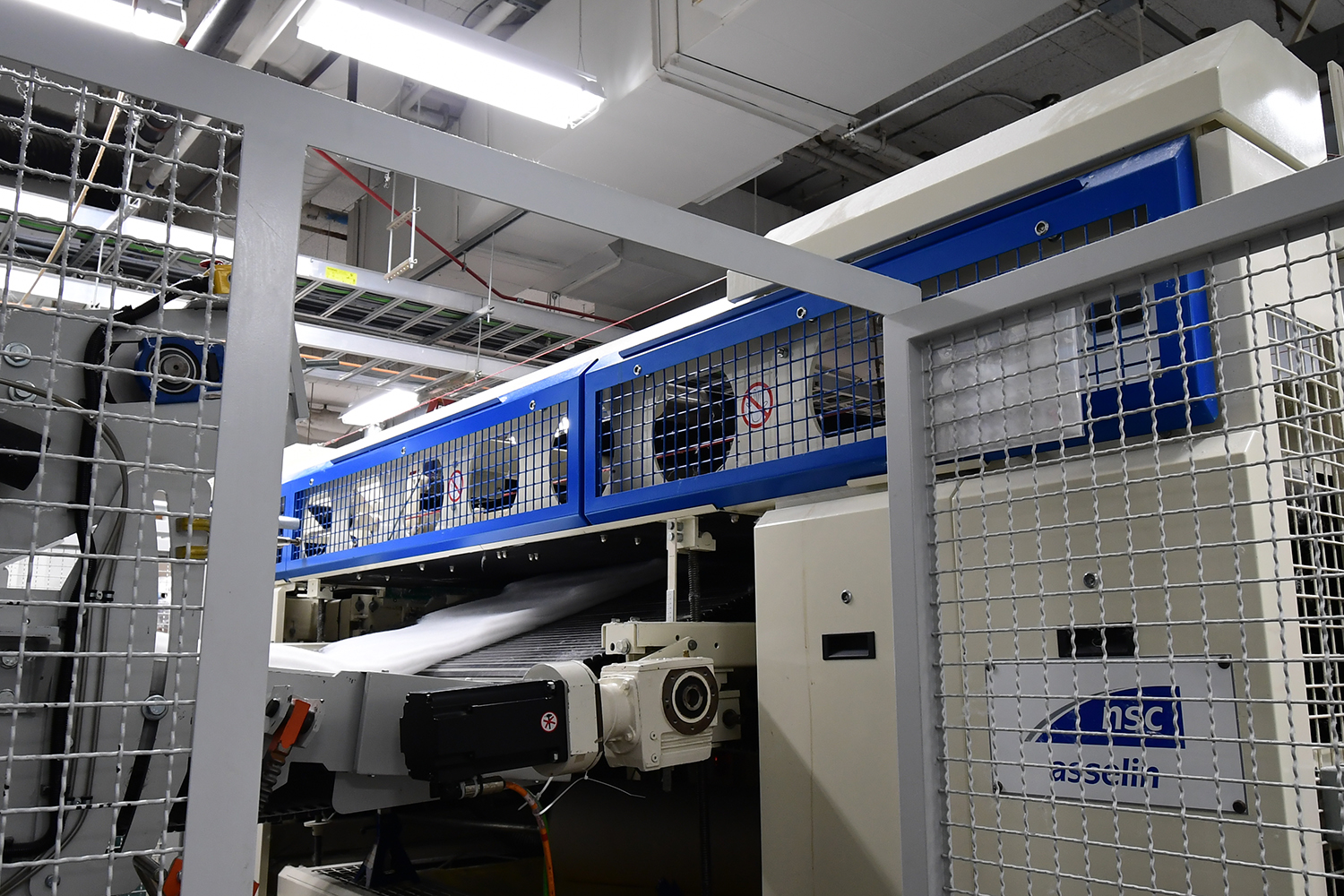

Carding is a leading nonwoven production process, which utilizes staple fibers of synthetic and natural sources as a raw material feedstock. The process involves the separation of a fiber mass by passing it over a series of drums with highly engineered tooth-like surfaces. Carding is a versatile process, offering the capability to blend a wide variety of fiber types and add finishes to achieve the desired functional characteristics. The carding process typically produces nonwoven webs that are highly oriented in the machine direction, although some newer carding systems can generate more randomly oriented webs with a better machine-direction (MD)/cross-direction (CD) ratio.

“While melt-spun processes like meltblown and spunbond have attracted a lot of attention in the nonwovens space in recent years, carding remains a strong platform option for a wide range of applications,” said Behnam Pourdeyhimi, Ph.D., executive director of NWI. “Not only does carding provide the flexibility to blend many different fiber types, the process is also capable of producing lightweight webs from 10-100 grams per square meter along with heavier-weight industrial fabrics up to 1,000 grams per square meter.”

The Carded Nonwovens Technology Short Course will examine the carding process from the bale opener to carding and bonding options, including cross-lapping, needle-punching, thermal bonding and hydroentangling. The course covers fibers and materials, the structure of nonwovens and how one measures properties such as formation, uniformity, fiber orientation, etc.

The bonding portion of the course is a critical piece, as it will consider structure-process-property relationships and how to optimize carded nonwoven materials to meet the requirements of the application. The course will also review fiber blending and composite formation.

Upon completing the course, attendees will have a comprehensive grasp on carded nonwoven production processes, including raw material selection, basic science knowledge, testing and the characterization used to create end-use products.

If you attend this course, you will:

- Learn how to leverage machine design, process and raw materials to develop products and optimize manufacturing efficiency.

- Get expert insight into nonwoven markets and applications for carded nonwoven technology.

- Gain an understanding of the nonwoven fabrics industry and the significant role carded nonwoven materials play in the world today.

Are you interested in attending the Carded Nonwovens Short Course?

The Carded Nonwovens Short Course is brought to you through a collaboration between NWI and INDA, Association for the Nonwoven Fabrics Industry. You can find the full schedule of upcoming NWI/INDA training courses, here.

- Categories: