Spunbond and Hydroentangling Lab

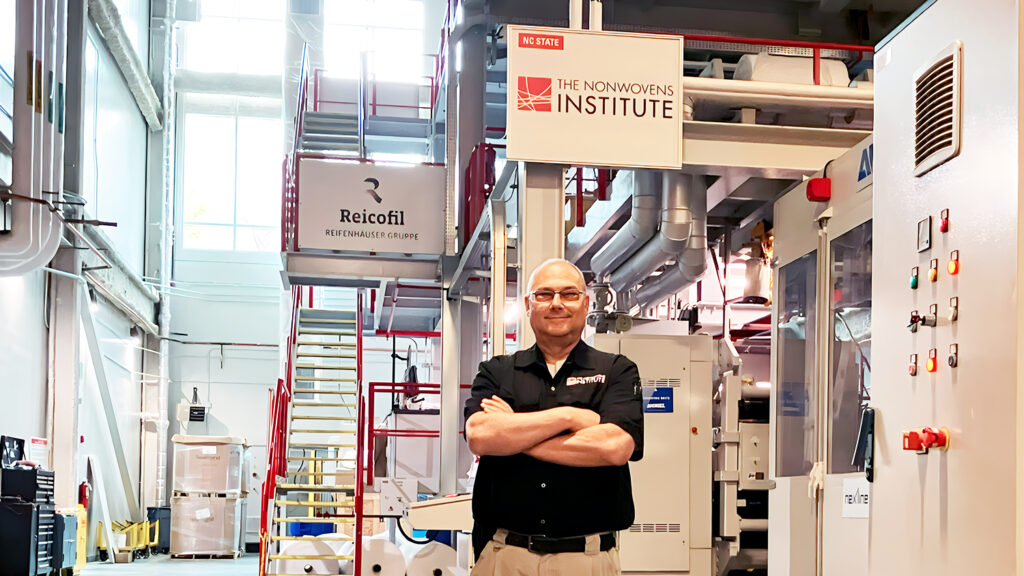

The Nonwovens Institute at North Carolina State University offers state-of-the-art technology and deep expertise in spunmelt nonwovens.

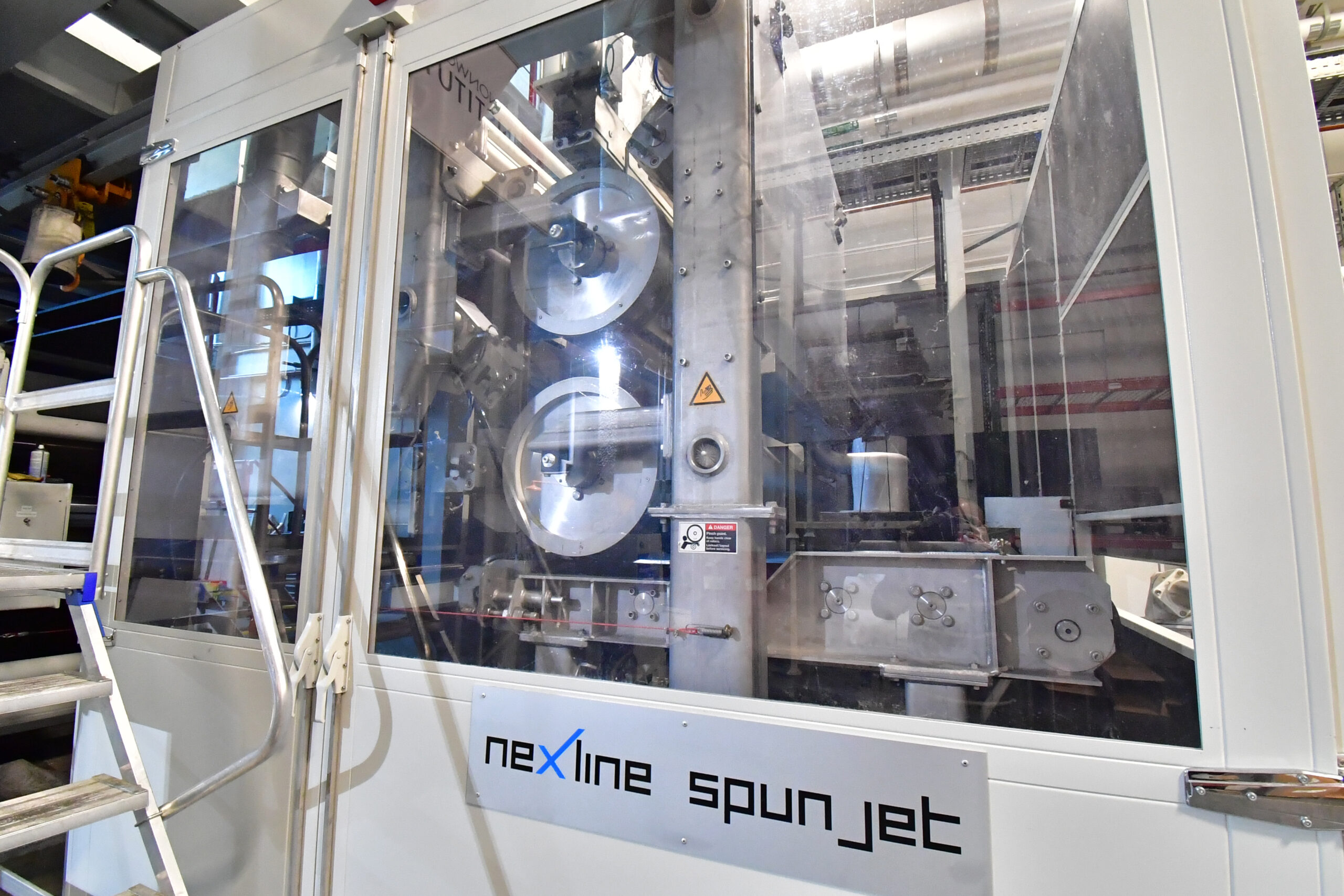

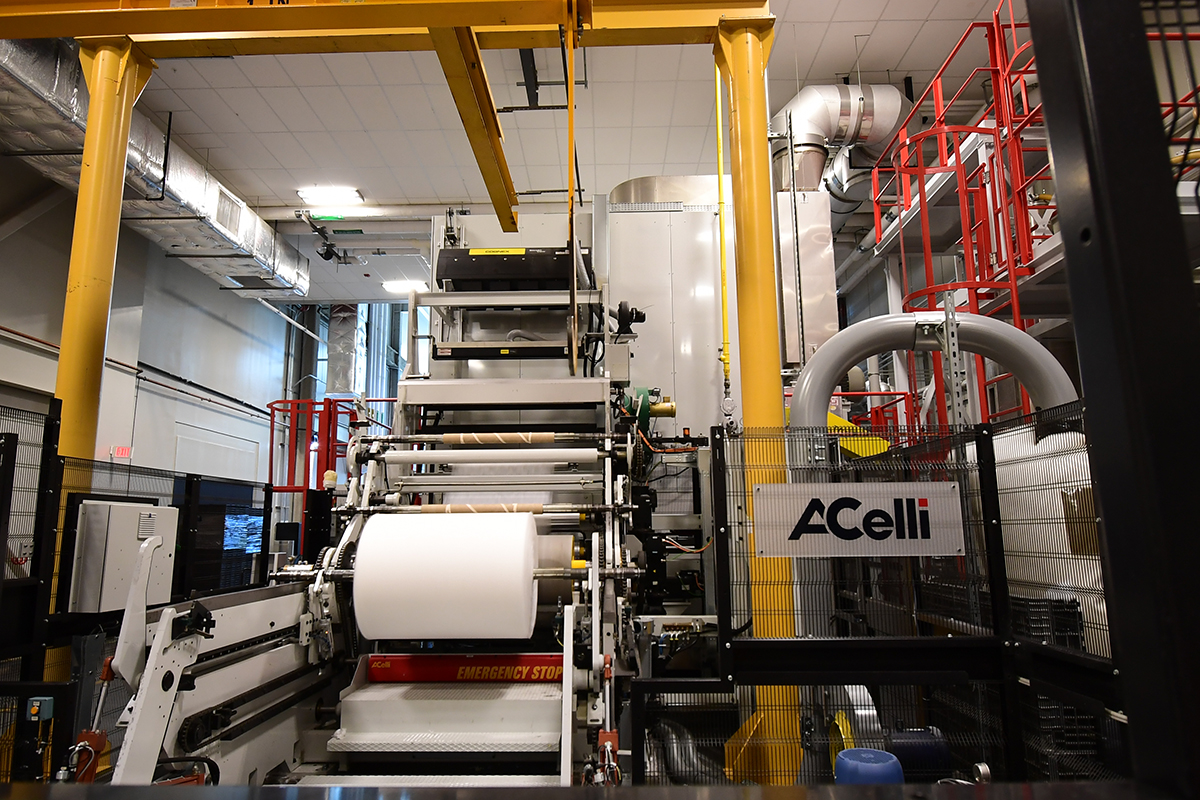

The Nonwovens Institute has decades of experience in spunmelt nonwovens, which in tandem with its in-house Reicofil spunbond line – soon-to-be upgraded to RF5 with full digitalization capability – provides you the opportunity to customize the web path to your specific application requirements. Thus, NWI’s Advanced Spunbond and Hydroentangling Pilot Lab also utilizes equipment from supporting partners – including Hills bico or mono filament die packs, two unwinds, an Andritz thermobonding calender, two Andritz Perfojet hydroentanglement units, a kiss roll, a through-air dryer, and a high-speed A.Celli winder and slitter. Importantly, this system includes in-line electrostatic charging capability (corona).

Following spunbond web laydown, the line offers several bonding methods via a hydroentanglement unit (one pre-entanglement injector, plus six additional injectors), a thermal calender (includes roll options for three bond patterns), a kiss roll unit, and a through-air dryer. The hydroentangling unit and thermal calender can also be used in combination.

Layers can be added either via a front-end unwind or after the web laydown via an unwind prior to bonding, supporting application variables such as, for example, combining cellulosics with spunbond in a hydroentangled structure. Finally, the web path concludes with slitting and winding.

Meet the Lab Manager:

Angelo Corino

NWI can run trials in many configurations, such as single-beam spunbond, and with a variety of fiber architectures. Fiber options include sheath-core bico, side-by-side bico, or homofilament, as well as more complex cross-sections, such as segmented pie and islands-in-the-sea. Resin options include PP, PE and PET, along with many others, including nylon, elastomers and biopolymers, such as PLA.

If you have questions about running trials at NWI, please email us at nonwovens@ncsu.edu.

If you wish to use the pilot equipment or have some testing done, you will need to have a Fabrication & Testing Agreement in place.

Spunbond Lab Documentation

Photo Gallery

NWI Spunbond and Hydroentangling Pilot Lab

Equipment Specifications

| Reicofil 4/Hills Inc. Bicomponent Spunbond Line | |

|---|---|

| Extruders | “A” – 120.0 mm (4.72”), Single Flight – 30 D “B” – 80.0 mm (3.15”), Single Flight – 30 D |

| Resins | PP, PE, PLA, PA & PET Other resins also possible with qualification |

| Resin Crystallizer & Dryer Units | Max drying capacity of 450 kg/hr |

| Resin Feeding (2 dosing units) | Unit 1: 3-component dosing, 500 kg/hr output Unit 2: 3-component dosing, 300 kg/hr output |

| Filament Spinning Speed | Up to 4500 m/min |

| Throughput | PP: 270 kg/hr/m (595.25 lbs/hr/m) PET: 400 kg/hr/m (881.85 lbs/hr/m) |

| Bicomponent Ratios | 40/60 to 85/15 |

| Fiber Designs (with Optional Additive add-on) | Homocomponent Bicomponent – Sheath-Core, Side-by-Side, Islands-in-the Sea, Segmented-Pie |

| Spinning & Web Width | 1060 mm (41.73 inches) |

| Number of Bicomponent Holes (holes per meter) | Sheath-Core via 6861, 5510, 3507 or 2687 Side-by-Side via 6861, 5510, or 2687 Islands-in-the-Sea, Segmented-Pie via 3507 |

| Spinnerets Hole Characteristics | Round 0.6mm diameter, L/D-4:1 Round 0.4mm diameter, L/D-4:1 Trilobal |

| Denier Range | PP – 2.0-6.0 dpf PET – 1.0-3.0 dpf |

| Filters | After extruder and in spin pack, wire mesh as required. |

| Throughput/Hole | 0.4 – 1.2 g/hole/min |

| Made Web Basis Weight Ranges | 10 – 200 gsm (Possibly higher depending on bonding) Typical for Calendering – 10-100 gsm Typical for Hydro entanglement – 50-200 gsm |

| Belt Speed Ranges | 20-400 m/min |

| Calendar Patterns | 19.87% bond area diamond/square 18.1% bond area elliptical 12.1% bond area, round |

| Electrostatic Charging (corona) | 4 charging bars, up to -50 kV per bar. |

| Possible Line Configurations | 1-Multiple unwinds included to make composites 2-Spun+Hydro+Hydro (for flexible structure) 3-Spun+Calendar+Hydro (soft thermal bonded) 4-Spun+Calendar (for thermally bonded web) 5-Spun+Oven (high bulk thermal bonded) 6-Water filtration for pulp/cellulose processing |

| Andritz Hydroentangling & Through-Air Dryer / Bonding System | |

|---|---|

| Width | 1100 mm |

| Manifolds | 7 total on 3 drums (includes pre-wet injector) |

| Orifice Strips | Please reference Lab Guidelines for details |

| Filtration | Sand and flotation cell |

| Dryer | Gas-fired Omega up to 260 C |

| Weight Ranges (Typical) | 50-200 gsm |

| Speed Ranges | 20-400 m/min |

If you have questions about running trials at NWI, please email us at nonwovens@ncsu.edu.