See NWI capabilities on display at INDEX™23

If you are attending the INDEX™23 exhibition next week in Geneva, members of The Nonwovens Institute will be showcasing technology that anchors our world-class pilot labs and supports our decades of expertise in nonwoven processes and applications.

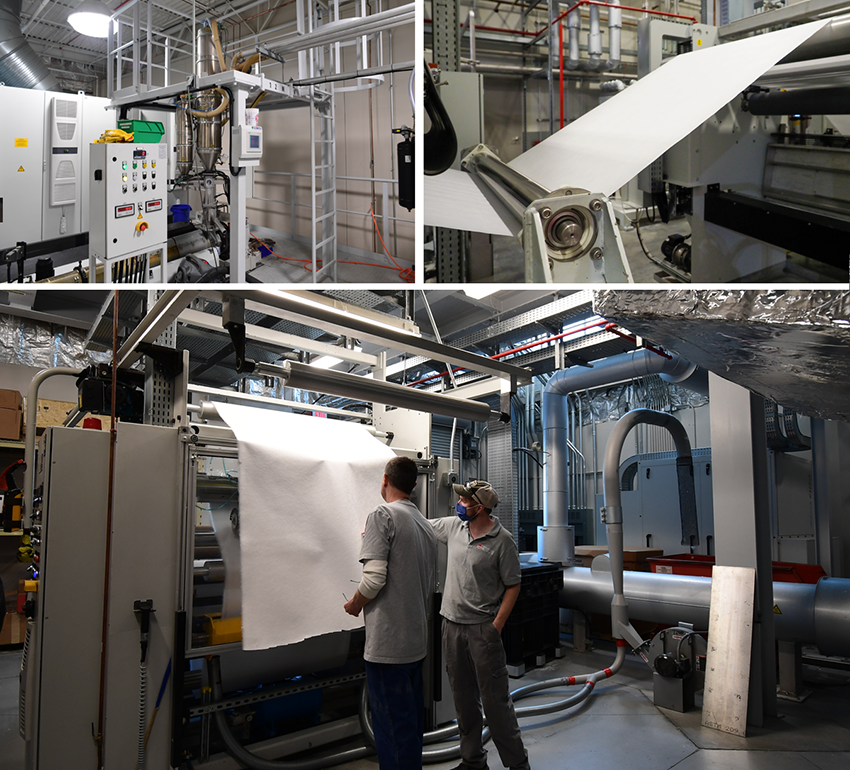

Meltblown Pilot Lab

NWI’s Meltblown Pilot Lab features a 1.2-meter wide Reifenhäuser Reicofil line with recently updated software and control systems. This machine, along with NWI’s many years of experience in developing meltblown nonwoven applications, provides you the ability to test a wide range of polymers, including polyolefins, polyamides, polyesters, elastomers, PLA and many others. Importantly, NWI’s meltblown line includes in-line electrostatic charging capability (corona).

To view technology housed within NWI’s Meltblown Pilot Lab, please visit our member companies at INDEX™23, including Reifenhäuser Reicofil (Stand No. 1531).

You can also download our Meltblown Pilot Lab Capabilities brochure.

If you have questions about meltblown processes for nonwovens, please engage NWI’s experts in this area.

Polymer & Fiber Science

Over the course of its 30-plus-year history working on a vast number of nonwoven trials, NWI has developed a unique understanding for how different fiber types and polymers perform in a wide range of nonwoven applications.

Experts working in NWI’s Fiber Science Lab specialize in the characterization of various polymers, biopolymers and additives for melt spinning pilot research. This lab is ideal for engaging in proof-of-concept with a minimum of input material required. Available technologies include Instron® rheology equipment (MVR and capillary rheometer), a Hills homo-component multifilament research line, Biax 15” meltblowing labline, fiber-forming Brabender® extrusion line (meltblowing), a Hills LBS-300 bi-component line (multifilament, monofilament, spunbond aspirator and meltblowing), and a Leistritz ZSE-18HPe twin-screw compounding extruder.

The newly added compounder is capable of feeding, compounding, devolatilizing, and pelletizing polyolefins (PP, PE), polyesters (PET, PBT, PTT, r-PET), polyamides (PA6, PA6.6, etc.), elastomers and biodegradable PLA, PBS, PHA polymeric compounds/masterbatches. In-house compounding capability means NWI can run various compounds and spin fiber within a single week, while also providing full process transparency.

To see some of the capability housed in NWI’s Fiber Science Lab, please visit our member companies at INDEX™23, including Hills, Inc. (Stand No. 2454)

You can also download our Fiber & Polymer Science Capabilities brochure.

If you have questions about polymer and fiber science for nonwovens, please engage NWI’s experts in this area.

Spunmelt & Hydroentangling Pilot Lab

NWI’s Advanced Spunmelt and Hydroentangling Pilot Lab features a Reicofil™ spunbond line – soon-to-be upgraded to RF5 with digitalization capability – which provides you the opportunity to customize the web path to your specific application requirements. Thus, NWI also utilizes equipment from supporting partners – including Hills bico or mono filament die packs, two unwinds, an Andritz thermobonding calendar, two Andritz Perfojet hydroentanglement units, a kiss roll, a through-air dryer, and a high-speed A.Celli winder and slitter. Importantly, this system includes in-line electrostatic charging capability (corona).

While at INDEX™23, you can see some of the technology included in NWI’s Spunmelt & Hydroentangling Pilot Lab by visiting our member companies, including Reifenhäuser Reicofil (Stand No. 1531), Hills, Inc. (Stand No. 2454), ANDRITZ Nonwoven and Textile (Stand No. 2114) and A.Celli Group (Stand No. 2130).

You can also download our Advanced Spunmelt and Hydroentangling Capabilities brochure.

If you have questions about spunmelt and/or hydroentanglement processes for nonwovens, please engage NWI’s experts in these areas.

Staple Fiber Pilot Lab

NWI’s Staple Fiber Pilot Lab is outfitted with two separate feeding systems from the opening equipment, which can be used independently to feed the card or a Scanfeed system for high-loft substrates.

This facility also includes a 1-meter wide Trützschler High-Speed Nonwoven EWK 413 Card, which processes fibers from 0.9 to 20 denier with basis weights ranging from 20 to 100 g/m2 direct lay.

An Andritz Profile 415-FD Crosslapper provides automatic batt width adjustment, automatic overlap control and adjustment, and full control over the number of layers, with automatic computation of the necessary delivery speed on the floor apron.

The facility includes two bonding technologies – needle-punch and through-air bonding. The pre-needler is a Trützschler single-board needle loom ENL followed by an Andrtiz A.50-RL needle loom, DF-4 version with 4-boards; two up, two down stroke.

For through-air bonding, the lab is outfitted with a Fleissner flat 4-zone impingement/through-air oven.

To view technology housed in NWI’s Staple Fiber Pilot Lab, please visit our member companies at INDEX™23, including Trützschler Group (Stand No. 1641), ANDRITZ Nonwoven and Textile (Stand No. 2114) and FiberVisions (Stand No. 2119).

You can also download our Staple Nonwovens Pilot Lab Capabilities brochure.

If you have questions about staple fiber processes for nonwovens, please engage NWI’s experts in this area.

- Categories: