NWI to Present Filter Media Course at FiltXPO™ – What Can Attendees Expect?

The Nonwovens Institute (NWI) is excited to be teaching the Filter Media Short Course Oct. 9-10 at FiltXPO™ in Chicago. This two-day training will provide a strong technical overview of nonwovens and their applications in air, aerosol and liquid filtration, technology options, unmet needs, and trends for future development. In the following article, the expert instructors who will be leading the Filter Media Short Course provide highlights on what attendees can expect to learn.

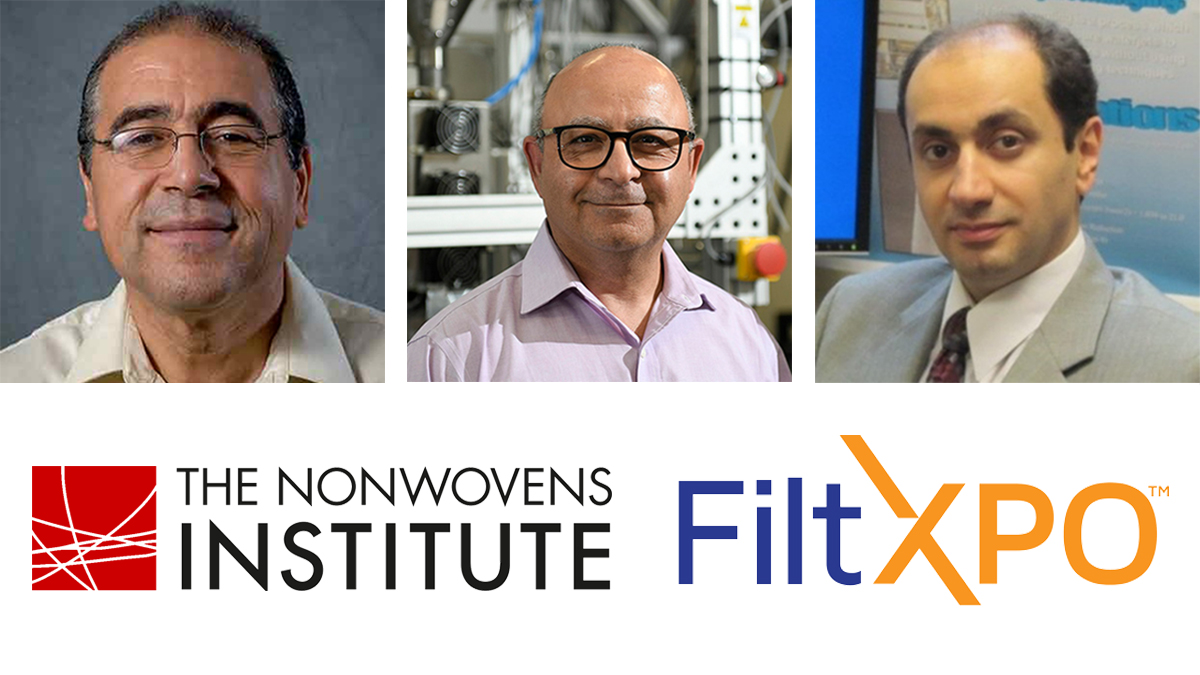

Hechmi Hamouda, Ph.D., Professor of Textile Engineering, NC State University (ret.)

Dr. Hamouda joined the faculty at NC State University in March 1985 after a short cursus with the U.S. Department of Energy’s National Energy Technology Laboratory. He has taught the mechanics of fibrous and biological structures, thermal sciences, and instrumentations at the undergraduate and graduate levels. He has expertise in a variety of liquid filtration applications.

During the Filter Media Short Course, Dr. Hamouda’s presentation will include the principles of liquid filtration, relationships between pore size, fiber dimensions and filtration performance of nonwoven media, with a focus on finding the right balance between filtration mechanism, efficiency and performance.

Dr. Hamouda’s presentation will include the principles of liquid filtration, relationships between pore size, fiber dimensions and filtration performance of nonwoven media, with a focus on finding the right balance between filtration mechanism, efficiency and performance.

Attendees will learn to recognize and select appropriate test methods, associated terminology and functionality for specific filter media. The course will provide an understanding of various filtration mechanisms and appropriate practices for selecting and evaluating filter media based on application requirements. How filters are packaged and the different types of filters employed for liquid filtration will also be covered.

The section on membrane microfiltration will cover the related processes, liquid membranes module design, configurations, and classification according to applications.

Behnam Pourdeyhimi, Ph.D., Professor and Executive Director, The Nonwovens Institute, NC State University

Dr. Pourdeyhimi joined NC State University as a Research Associate immediately after completing his Ph.D. at the University of Leeds in 1982. Soon, he left for other opportunities, Cornell (2 years), the University of Maryland (11 years) and Georgia Tech (4 years), before returning to NC State in the 1998-1999 academic year. Dr. Pourdeyhimi was appointed Director of the Nonwovens Cooperative Research Center (NCRC) in 2000, and he successfully led the transition of NCRC into what is now known as The Nonwovens Institute (NWI). His work in the area of filtration won him the 2015 O. Max Gardner Award for its “contribution to the welfare of the human race.”

This course will provide a foundational understanding for how filter media is made, covering relevant processes, such as spunbond, meltblown and electrospinning. We will focus on the structure-property relationship of filter media, as well as the process for evaluating filters, including discussion of ASHRAE and ISO standards.

Notably, we will be adding a significant component to the course on electrostatic charge. This section will discuss not only how charge is created, but also how to measure and store charge within filter media.

Notably, we will be adding a significant component to the course on electrostatic charge. This section will discuss not only how charge is created, but also how to measure and store charge within filter media.

Upon completion of the course, attendees will understand the principles, test methods, structure and the processes employed to make filter media.

Hooman Tafreshi, Ph.D., Associate Professor, Mechanical and Aerospace Engineering, NC State University

Dr. Tafreshi is a faculty member in the Department of Mechanical and Aerospace Engineering at NC State University and Associate Director for Research at The Nonwovens Institute. Dr. Tafreshi’s research focus is on multiphase fluids and particle/droplet transport through fibrous materials with applications in filtration and separation sciences.

My presentation during the Filter Media course will cover the physics of air and aerosol filtration. We will discuss the importance of filtration and best practices for manufacturing filters, with particular emphasis on nonwovens, textiles, polymers and fibers.

With all of the problems associated with the COVID-19 pandemic, one of the good things that came out of it was that people now recognize the importance of the quality of the air we breathe. The quality of air and water is just as important as the quality of the food we consume, and more people now understand this as a fundamental truth, which is shining a light on filtration.

During this course, we will discuss how to manufacture a filter that delivers the necessary filtration efficiency, while also being cost effective. From an engineering perspective, it is possible to design a filter that can capture just about anything. However, the “perfect filter” comes with a price point that may not be accepted by the market. With nonwovens, there are a lot of options available for filter media, and we will consider options for designing a filter that provides the appropriate level of filtration efficiency for the application with a cost of manufacturing that is in line with market expectations.

With nonwovens, there are a lot of options available for filter media, and we will consider options for designing a filter that provides the appropriate level of filtration efficiency for the application with a cost of manufacturing that is in line with market expectations.

FiltXPO™ is presented by INDA, the Association of the Nonwoven Fabrics Industry. INDA serves hundreds of member companies in the nonwovens/engineered fabrics industry to achieve business growth. Since 1968, INDA helps members convene and connect, innovate and develop their businesses. INDA’s educational courses, business intelligence and market insights, test methods, consultancy and issue advocacy help members succeed by providing information they need to better plan and execute their business strategies.

Based at the Centennial Campus of North Carolina State University, The Nonwovens Institute (NWI) is a partnership among stakeholders spanning the breadth of the nonwovens value chain. Operating on an “Open Innovation” platform and covering the full Technology Readiness Level (TRL) range, NWI engages government, industry and academia to enable next-generation nonwoven solutions to mission-critical challenges. NWI trains the future leaders of our industry, with a service offering that includes fundamental research, workforce development, testing and fabrication, product development and product incubation. NWI is supported by more than 45 industry-leading member companies/organizations.

Are you interested in attending the Oct. 9-10 Filter Media Short Course?

- Categories: