Job Title: Research Specialist

Years at NWI: Since July 2023

Years in Nonwovens/Materials Science: 4

Favorite Nonwoven or Something Related to Nonwovens: Meltblown/Nonwovens for Medical Applications

The Nonwovens Institute (NWI) is excited to welcome the newest addition to our team, Ms. Natalie Young, who joined NWI as a Research Specialist in July 2023. Natalie developed her skills in research while pursuing a bachelor’s degree in Textile Technology at the Wilson College of Textiles (COT) at NC State University.

During her time in COT, Natalie served as a research assistant on several projects prior to earning her degree in May 2023.

Natalie has settled in quite well in her early days at the Institute, leveraging her skillset to benefit a variety of NWI research projects under the guidance of Mehmet Dasdemir, Ph.D., NWI’s Director of Product Development, and Benoit Maze, Ph.D., NWI’s Director of Education and Administration.

What was your experience leading up to your joining NWI?

I am a native of Raleigh, North Carolina, and I attended NC State University from 2019-2023. While pursuing my degree in Textile Technology through the Wilson College of Textiles, I assisted on two research projects with graduate students studying under Tushar Ghosh, Ph.D., a William A. Klopman Distinguished Professor at NC State. Both of these projects were in the SMARTextiles (Self-Monitoring, Adaptive and Responsive Textiles) Lab here at NC State.

One of the projects focused on integrating pressure sensors into a textile sleeve for prosthetic wearers. The sleeve was designed to help troubleshoot discomfort issues prosthetic wearers face due to poorly fitted prosthetics. The other project I worked on in the SMARTextitles Lab was focused on improving the performance of electronics integrated into flexible fabrics. On this project, I helped test electronics across fabric interconnects – the point where two pieces of fabric are joined together – which is a common source of failure in eTextiles.

As I was completing my degree in Textile Technology, I was invited to attend ITMA Milan – the world’s largest international textile and garment technology exhibition – and work the Wilson College of Textiles booth during the event. The show was massive with a lot of learning experiences – and I was able to incorporate some vacation time into the trip as well – so it was a great experience for me overall.

What kind of work have you done/do you do at NWI? What do you find exciting/interesting about your work at NWI?

Prior to joining NWI as a full-time employee, I had a short internship at the Institute in March 2023. During this time, Dr. Maze worked with me to help me learn more about our labs and the different nonwoven processes, and he helped me understand the types of projects NWI typically works on within academia, as well as in industry.

Since joining NWI as a full-time employee, I have been working with both Dr. Dasdemir and Dr. Maze to support the research projects they are leading. Dr. Pourdeyhimi has also worked with me to help accelerate my learning curve through regular updates on our project pipeline and including me in our training courses.

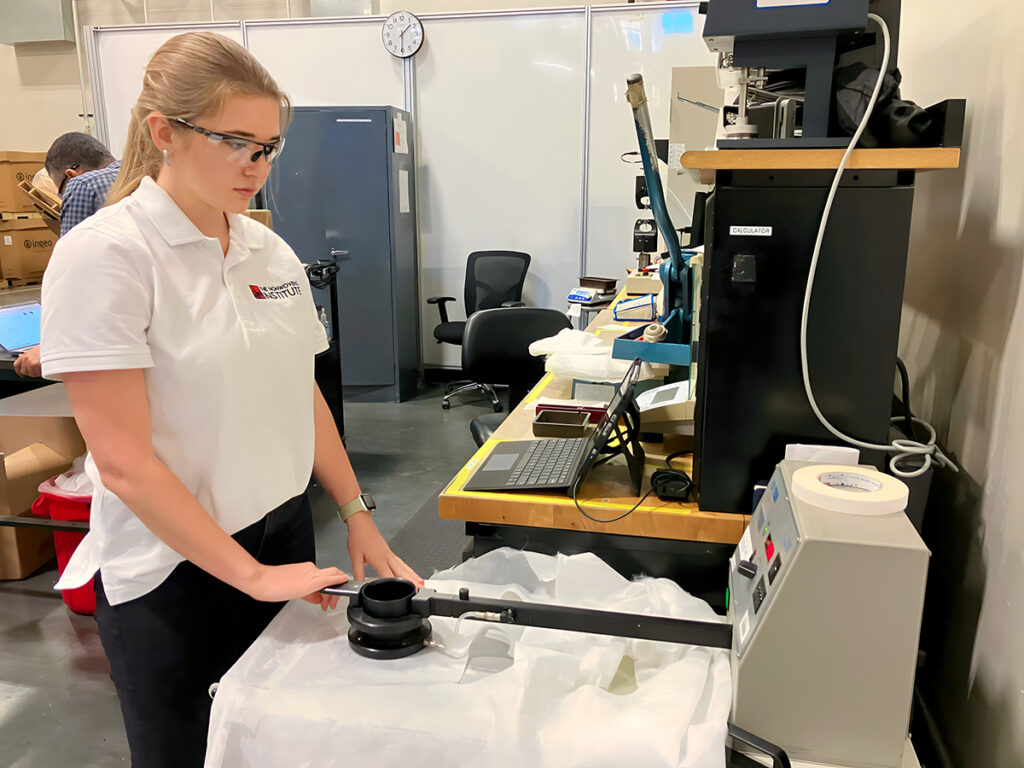

The bulk of my daily activity to date has been focused on developing trial plans, helping to run trials, and performing the physical testing and data analysis required to support our projects.

I’ve also had the opportunity to attend the NWI Industrial Advisory Board (IAB) meetings – learning more about the research projects in our industry-identified fundamental research program – as well as the RISE® – Research, Innovation & Science for Engineered Fabrics – Conference, which is hosted each year here on NC State’s campus.

Why did you choose what you chose in the “Favorite Nonwoven or Something Related to Nonwovens” item above?

I’ve enjoyed learning about and working with the meltblown process. I find it fascinating that you can take these little polymer pellets and turn them into super-fine fibers to produce fabrics with some truly amazing performance characteristics. It’s also interesting to see how minor adjustments to the process can significantly influence the structure and properties of the materials being produced.

In terms of applications, I would say medical is my favorite area. Developing fabrics that can help protect people when they are in a vulnerable state is an inspiring and noble aim that makes you feel like you are making a positive impact through your work.

When you are not working at NWI, what are your personal interests, hobbies … any activities you enjoy during your free time?

In my free time, I love cooking, exercising and traveling.

During my recent trip to ITMA, I took some time to tour Barcelona, Geneva, the Swiss Alps and Valencia – in addition to Milan where the show was located.

This spring I have a trip planned to France and the Netherlands, visiting Paris and Amsterdam, which I’m very much looking forward to.

If you have questions about NWI’s research and development capability, you can reach Natalie at nlyoung@ncsu.edu.

- Categories: