Morgan Gilbert, Hydroentangled Cellulosic Nonwovens as Potential Reusable and Biodegradable Fabrics

Morgan Gilbert

Degree Type: Master’s (NOTE: Morgan is currently pursuing a Ph.D. in Fiber and Polymer Science at NC State University and is engaged in a new NWI research project. More details on Morgan’s new research project will be provided as they become available.)

Graduation Year: 2023

School/Department: Wilson College of Textiles, NC State University

Program/Focus: M.S. Textiles with a focus in Textile Technology and a Graduate Certificate in Nonwoven Science and Technology

Research Project: Hydroentangled Cellulosic Nonwovens as Potential Reusable and Biodegradable Fabrics

Professor/Faculty Advisor: Dr. Behnam Pourdeyhimi, NWI/NC State University

How did you come to have an interest in nonwovens?

I came to NC State two years ago to study textiles, and one of the very first classes I took was about nonwovens. Although I had a very limited understanding of the field prior to starting this program, that nonwovens course quickly became my favorite class as I progressed through my first semester of graduate school. That class inspired me to continue learning more about the topic of nonwovens throughout my time at graduate school. Now, I have earned the Graduate Certificate in Nonwoven Science and Technology that is offered by NC State. This means that I have taken various nonwovens courses spanning across a plethora of topics related to nonwoven science and technology. These courses have provided me with an in-depth understanding of nonwovens, from the materials that make up nonwovens and the processes used to produce them to methods for characterizing nonwoven textiles and the variety of end-use applications that these fabrics possess.

Why are your research/findings particularly important/compelling for nonwovens applications?

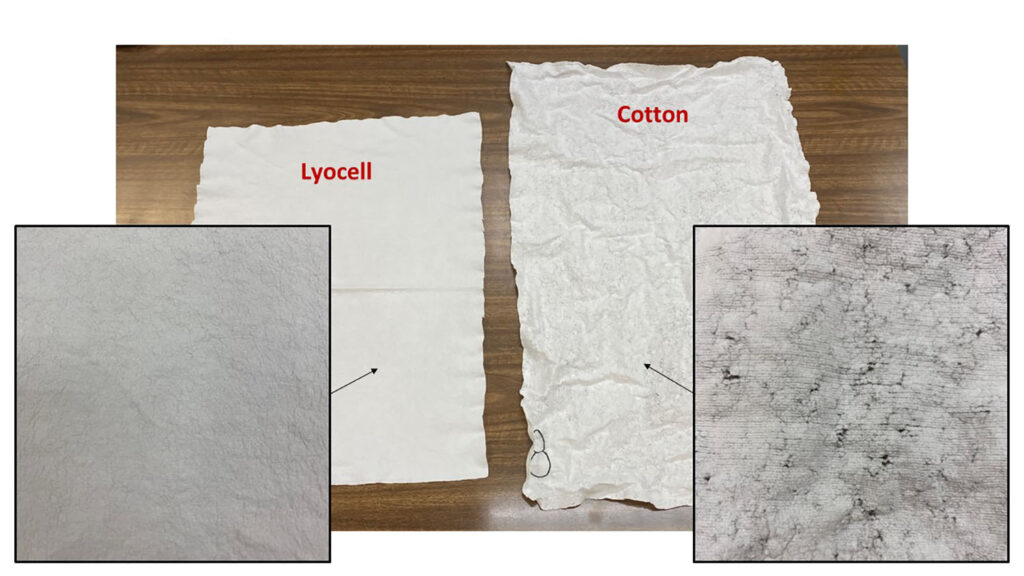

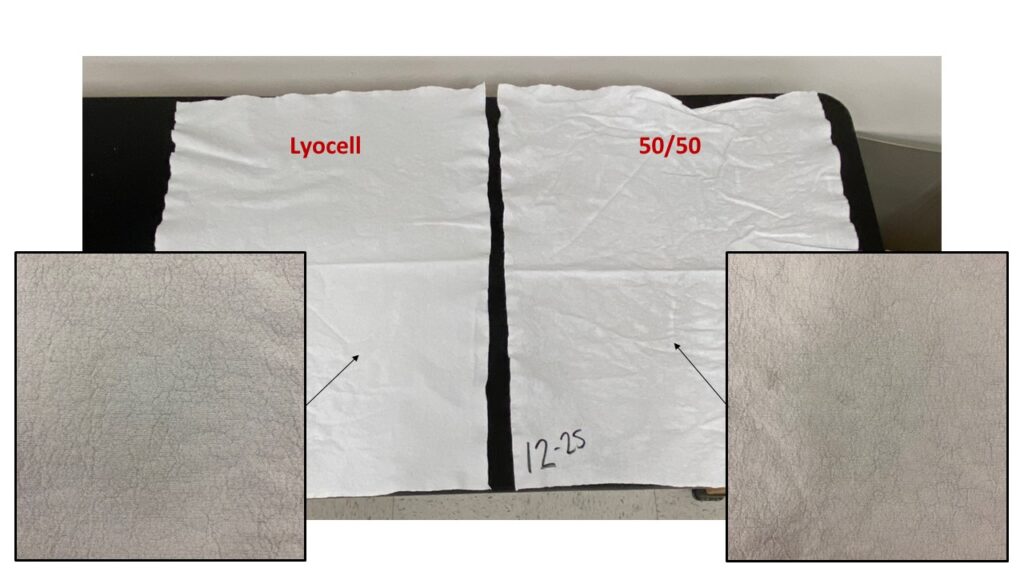

My NWI research project focuses on investigating the reuse potential of hydroentangled cellulosic nonwovens. It is well known that hydroentangling can be done at high energy levels, resulting in a very strong bond in many cases. The purpose of my project is to use high-energy hydroentanglement to thoroughly bond webs of cellulosic fibers which will, theoretically, result in a durable nonwoven fabric with a strong enough bond to withstand repeated laundering (25 wash cycles), thus rendering the fabric reusable. Since the nonwoven fabric consists of only cellulosic fibers, it would be considered to be biodegradable as well.

Although high energy levels of hydroentanglement will likely result in a strong bond that could be durable enough to withstand repeated laundering, it may also cause some undesirable effects. It is known that when a lot of hydroentangling energy is used, the resulting nonwoven tends to be very stiff and rigid with a rough texture. For that reason, we specifically chose to use lyocell as one of the cellulosic fibers for this project. Lyocell tends to fibrillate, or split into smaller fibers, when hydroentangled, especially when hydroentangled at high energy levels. This will, hopefully, offset some of the unwanted effects that intense hydroentangling may cause since smaller fibers tend to enhance softness and reduce stiffness.

This research is so important to this field because nonwovens currently have major limitations and challenges when it comes to sustainability. Nonwovens are commonly used for disposable, single-use products and applications that generate a large amount of waste. Although some reusable nonwovens do exist, they are at least partially synthetic. This means that once they reach their end of life and, ultimately, must be disposed of, they will not break down and decompose.

Achieving both reusability and biodegradability within nonwovens is crucial for addressing these environmental issues within this field.

Where do you see yourself upon completion of your studies? Where do you see yourself 5-10 years into the future as you progress in your career?

I have been fortunate enough to recently intern for the global filtration company, MANN+HUMMEL. This internship has reaffirmed my deep interest in the field of filtration and my passion for making the world a cleaner, healthier, and all-around better place.

Although I thoroughly enjoy the field of filtration, and could certainly see myself pursuing a career in that area, I still am extremely enthralled by the field of nonwovens as a whole. Essentially, I see myself working in any nonwovens-related field, ideally in a role that involves innovation, new product development, and/or research and development with a focus on sustainability.

When you are not studying and doing your nonwovens research project, what are your personal interests, hobbies … any activities you would like to highlight?

I have a variety of hobbies that I like to keep up with in my free time, but one of my absolute favorite hobbies is dance. Dance has been a huge part of my life for many years.

I took dance classes for several years as a teenager and was on my college’s dance team for all four years of my undergraduate experience. Although I am not currently on a team, I still try to practice or take classes whenever possible.

In addition to dance, I also enjoy partaking in other various artistic hobbies in my free time, such as crocheting and knitting. Aside from these hobbies, I also have a huge interest in travel. My favorite place that I’ve traveled to so far has been Sevilla, Spain. Although I have not often had the time or resources to travel while in graduate school, I hope to do so again in the near future.

For more information on how you can engage with NWI as a student researcher, visit our “For Students” page.

- Categories: