Fiber and Polymer Science Lab

The Nonwovens Institute at North Carolina State University offers deep expertise in fiber and polymer science to support your project goals.

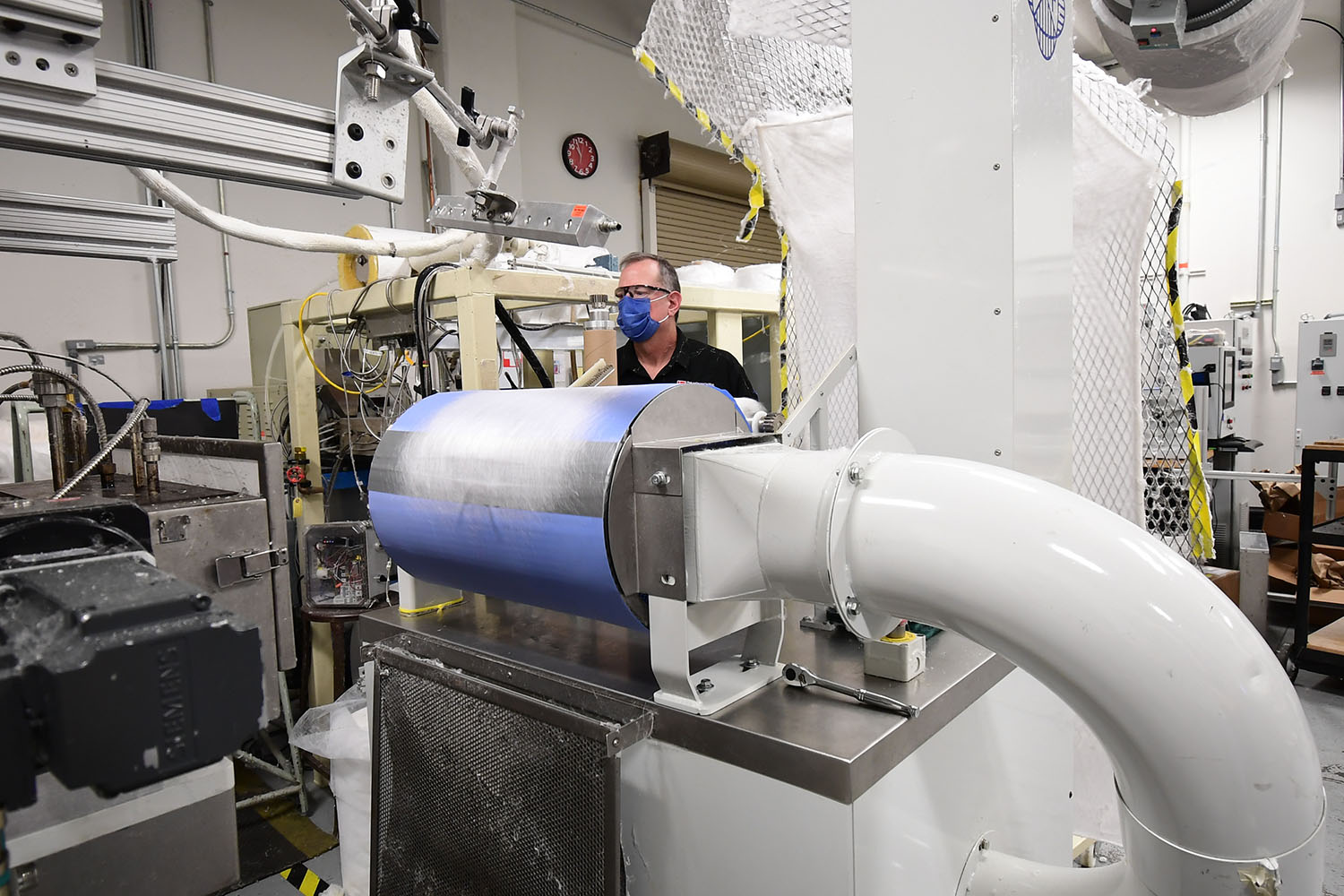

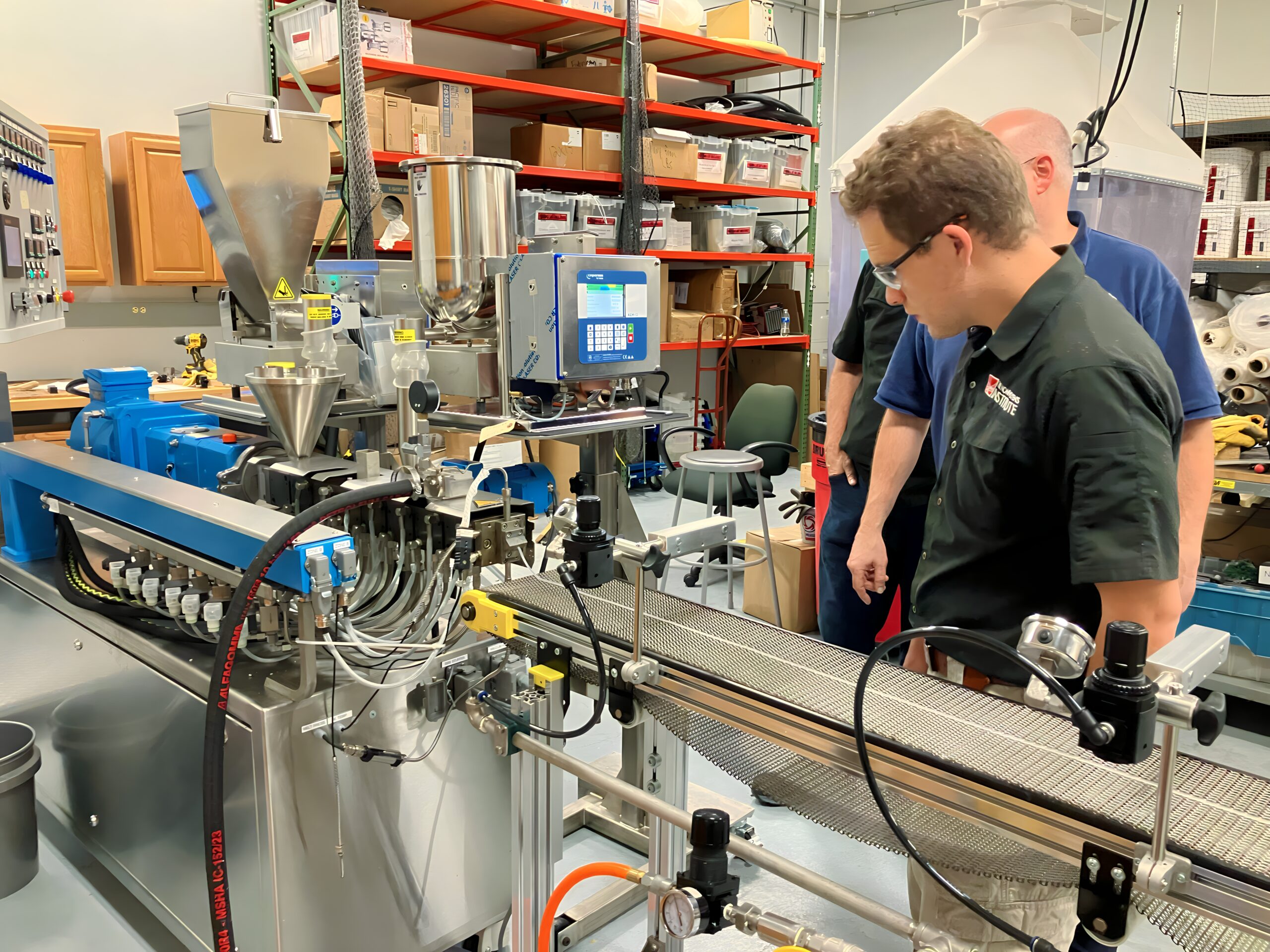

Experts working in The Nonwovens Institute’s Fiber and Polymer Science Lab specialize in the characterization of various polymers, biopolymers and additives for melt spinning pilot research. This lab is ideal for engaging in proof-of-concept with a minimum of input material required.

Available technologies include Instron® rheology equipment (MVR and capillary rheometer), a Hills homo-component multifilament research line, Biax 15” meltblowing labline, fiber forming Brabender® extrusion line (meltblowing), a Hills LBS-300 bi-component line (multifilament, monofilament, spunbond aspirator and meltblowing), and a Leistritz ZSE-18HPe twin-screw compounding extruder.

The newly added compounder is capable of feeding, compounding, devolatilizing, and pelletizing polyolefins (PP, PE), polyesters (PET, PBT, PTT, r-PET), polyamides (PA6, PA6.6, etc.), elastomers and biodegradable PLA, PBS, PHA polymeric compounds/masterbatches. In-house compounding capability means NWI can spin fiber within a single week, while also providing our partners full process transparency.

Lab Capabilities Include:

- Melt rheology

- Filament spinning

- Meltblowing

- Dual-beam meltblowing with particle dispersing

- Mini-spunbond

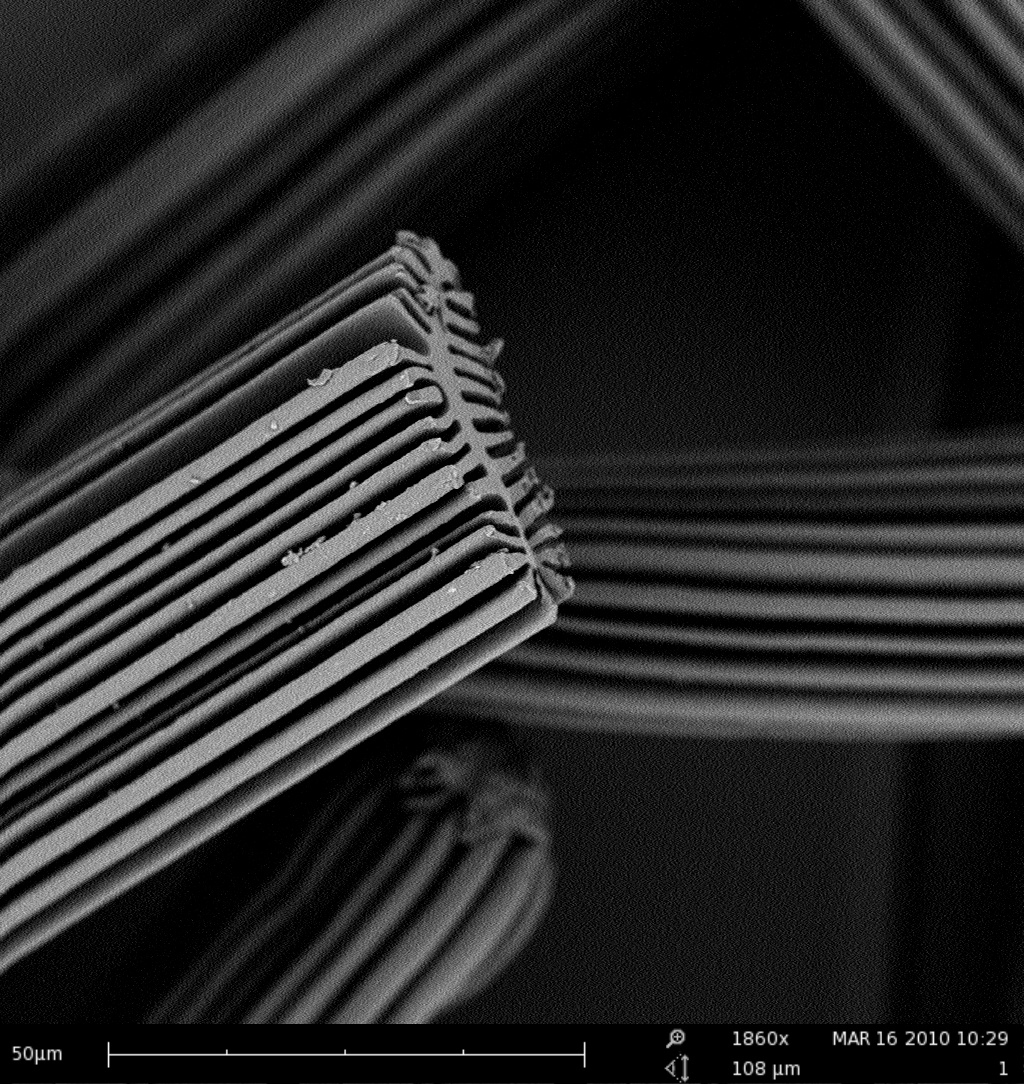

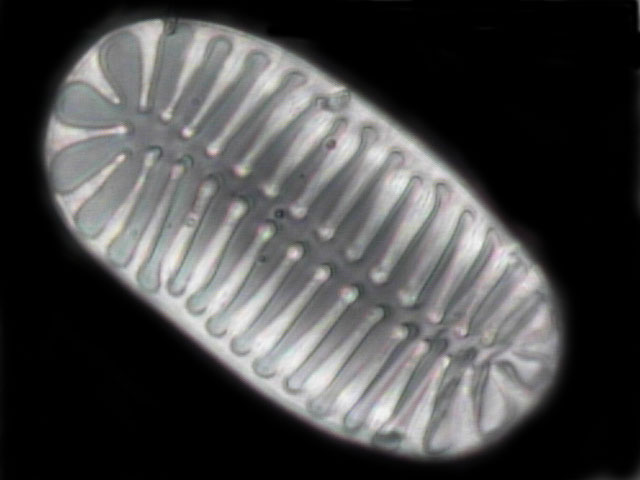

- Measuring fiber size and checking filament cross section

- Quick denier measurements

- Testing moisture content in ppm

Polymer Expertise Includes:

- A full lifecycle view of polymers from structure to properties to processing to application

- Polymer characterization

- Polymer thermal analysis

- Polymer chemical analysis

- Polymer compounding and blending

If you have questions about running trials at NWI, please email us at nonwovens@ncsu.edu.

If you wish to use the pilot equipment or have some testing done, you will need to have a Fabrication & Testing Agreement in place.

For each pilot equipment, we provide the following guidelines and templates. The guidelines contain the specification of the relevant machinery as well as the cost of using the various options. The trial plan provides a starting point outline of important test configuration options and choices, as well as test matrix design to ensure needs are met.

Photo Gallery

NWI Fiber and Polymer Science Lab

Equipment Specifications

| Filament Spinning | |

|---|---|

| Hills Multifilament Research Line ▪ Extruder diameter: 1” ▪ Extruder 30:1 L/D ▪ Fiber extrusion up to 320 C ▪ Up to 4 kg/hr PET ▪ Round, hollow and trilobal cross-sections ▪ Screw includes Maddox mixing ▪ Direct connection of extruder to spin head ▪ Variable quench air flow rate, chilled ▪ Heated godets with separator rolls | Hills LBS 300 ▪ Bi-component line ▪ Extruders diameter: 3/4” ▪ Extruders 30:1 L/D ▪ Fiber extrusion up to 310 C ▪ Up to 3 kg/hr PET per extruder ▪ 2” spunbond aspirator and collector drum ▪ 4” meltblowing die and collector drum ▪ Monofilament and multifilament ▪ Plates for homo, side-by-side, sheath/core, 16 segment pie and 36 islands-in-the-sea |

| Melt Rheology | |

|---|---|

| Instron® Ceast MVR ▪ Measures g/10 min ▪ ASTM D-1238 A/B/C; ISO 1133 ▪ 50 C-450 C range ▪ 2.16 Kg & 5 Kg weights ▪ 2.095 mm ID x 8 mm die ▪ 1.045 mm ID x 4 mm die | Instron® Ceast SmartRheo Capillary Rheometer ▪ Measures shear vs viscosity ▪ 2 load cells capacity: 20 kN ▪ 50 C-450 C range ▪ 200-10,000/s ▪ 30:1, 20:1. 5:1 dies |

| Meltblowing | |

|---|---|

| Biax 15” Labline ▪ Fiber extrusion up to 315 C ▪ Air temp up to 300 C ▪ Up to 4 kg/hr PET ▪ .009” x 4 row capillary die ▪ .020” x 2 row capillary die ▪ Horizontal design ▪ Mobile collector drum vacuum motor ▪ Dual-beam with particle dispersing | Brabender® Meltblowing ▪ Fiber extrusion up to 350 C ▪ Air temp up to 300 C ▪ Up to 4 kg/hr PET ▪ 5” Biax meltblowing dies ▪ Mobile collector drum vacuum motor ▪ Dual-beam with particle dispersing |

| Compounding |

|---|

| Leistritz ZSE-18HPe Twin-Screw Extruder ▪ Screw diameter: 17.8 mm ▪ Flight depth without tolerance: 3 mm ▪ OD/ID: 1.5 ▪ Length-to-diameter ratio (L/D): 40:1 ▪ Max screw speed: 1,200 RPM ▪ Motor power: 10 kW ▪ Max torque: 71 Nm ▪ Max temperature: 350 C ▪ Feed system: 3-component K-Tron gravimetric ▪ Side stuffer: Self-wiping twin screw solids metering ▪ Strand pelletizing group: cooling belt and pelletizer |

If you have questions about NWI or our service offering, please contact us at nonwovens@ncsu.edu.