Anastasia Timofeeva, Dynamic, In-situ Characterization of Failure Modes in Fiber Spinning

Anastasia Timofeeva

Degree Type: Ph.D.

Expected Graduation Year: 2024

Department/School: Department of Mechanical and Aerospace Engineering, NC State University

Program/Focus: Mechanical Engineering

Research Project: Dynamic, In-situ Characterization of Failure Modes in Fiber Spinning

Professor/Faculty Advisor: Dr. Kara Peters, NC State University; Dr. Mark Pankow, NC State University

How did you come to have an interest in nonwovens?

I am a graduate research assistant in the Smart Composites Laboratory, where my general research interests focus on non-destructive structural health monitoring (SHM). In my previous studies I have investigated how the thickness of polymer thin films affects their mechanical properties utilizing piezoelectric sensors and laser doppler vibrometry. That led me to the application of SHM in the field of nonwovens, where fibers or nonwovens can be classified as healthy or damaged based on the defects present in the material. The ability to non-destructively evaluate the health (quality) of the material produced can introduce opportunities in both research and development and production quality engineering fields.

Why are your research/findings particularly important/compelling for nonwovens applications?

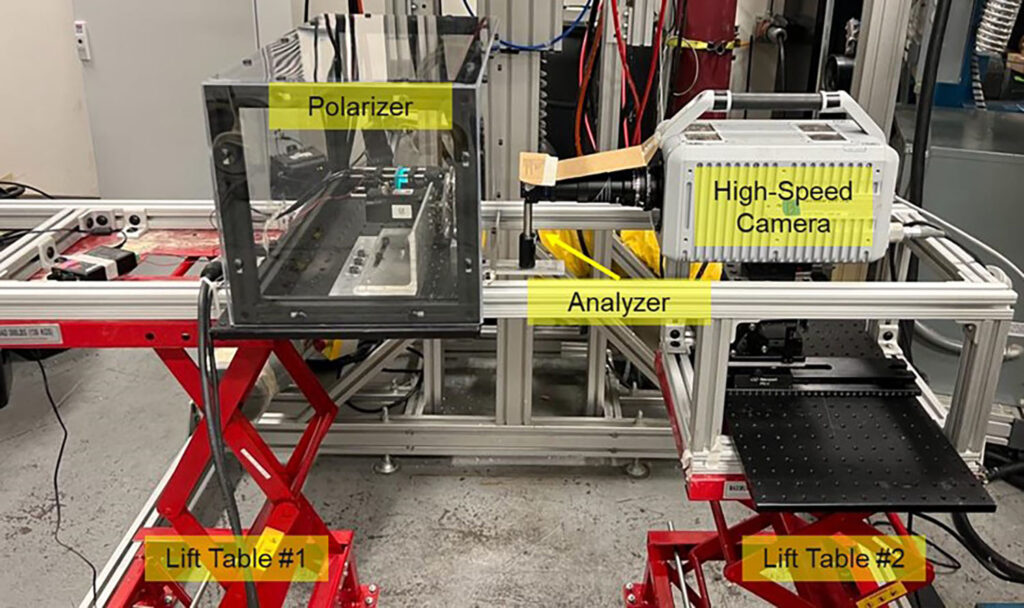

My research focuses on the development and implementation of a high-speed polarization imaging technique for in-situ defect detection in polymer fibers during fiber spinning production. Fiber spinning is a complex process in which many material and process parameters can result in undesirable defects in the finished product. Polymer fibers undergo flow-induced crystallization that influences the final quality of the fibers and the nonwoven material. Modern, commercial fiber and nonwoven manufacturing is a very high-speed process where continuous monitoring of these parameters and attributes is challenging. The ability to recognize processing irregularities would reduce the downtime for production lines, as well as provide in-situ quantitative data that can be used for optimization of production process parameters. Overall, this study can help researchers develop an understanding of why defects occur and relate polymer properties to spinning conditions.

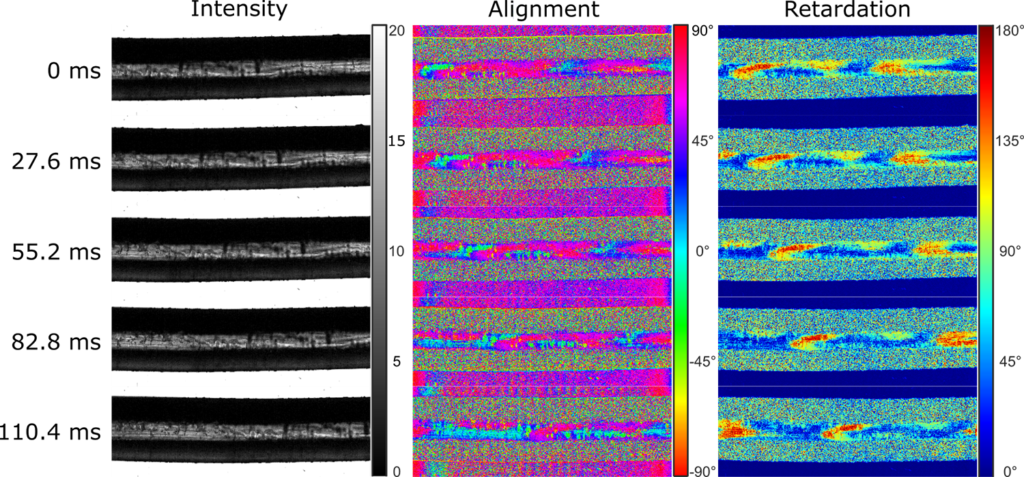

In my work, I am exploring the use of high-speed polarized light imaging to measure internal stress fields and the orientation of polymer chains within the fibers as they are being produced. While working for NWI, I have adapted two optical methods for stress field (defect) measurements within the fibers. In the first method, Quantitative Polarized Light Microscopy (QPLM), I have developed a motion-tracking algorithm and an improved data processing method that enables accurate data analysis while minimizing noise and spatial lag. The second method, Instant polarized light microscopy pi (IPOLπ), increases the imaging acquisition rates, while eliminating the need for motion tracking, thus reducing the computational cost for image analysis.

Learn more about Anastasia’s NWI research project in the following video short:

Where do you see yourself upon completion of your studies? Where do you see yourself 5-10 years into the future as you progress in your career?

My career goals include working in an interdisciplinary R&D or production division related to imaging and data analysis. If possible, I would like to implement the techniques that I have learned in my Ph.D. studies in a future job. I would also like to be able to travel internationally to learn and share my technical skills among other professionals. Long-term, I aim to advance to a senior-level engineering leadership position where I can further develop relationships within my professional community.

When you are not studying and doing your nonwovens research project, what are your personal interests, hobbies … any activities you would like to highlight?

In my free time I like to spend time with friends and family. I enjoy outdoor activities such as kayaking and biking. I have two cats, Marti and Jessi. Additionally, I like to make craft projects. My most recent projects include personalized pictures, ornaments and coasters made with a laser cutter.

Anastasia’s Recent Publications:

- “Accelerating imaging frequency in high-speed polarization imaging through data modeling,” Optical Engineering, Vol. 63, Issue No. 4, https://doi.org/10.1117/1.OE.63.4.043103.

For more information on how you can engage with NWI as a student researcher, visit our “For Students” page.

- Categories: