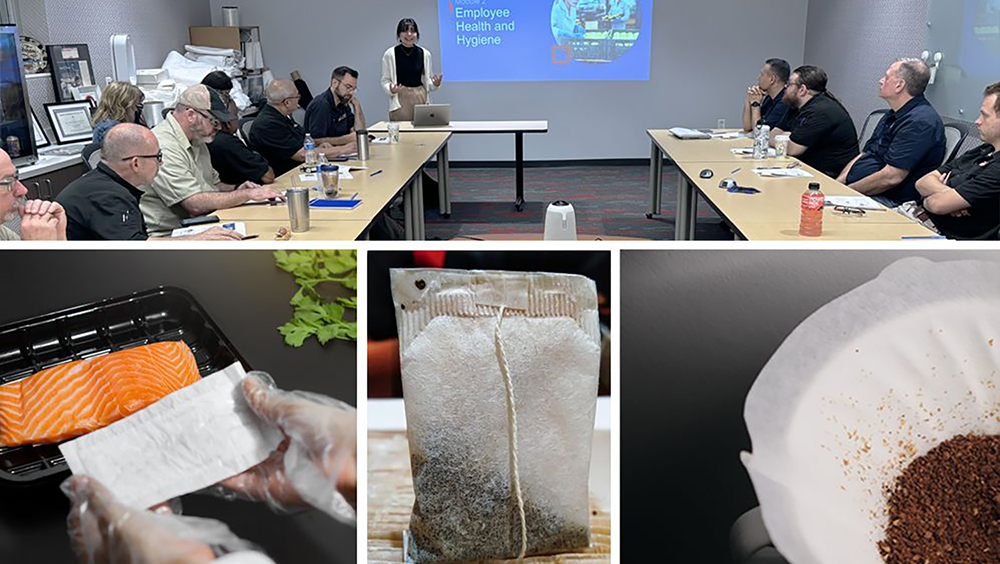

Continuing to build upon its strong culture of quality-based manufacturing practices, The Nonwovens Institute (NWI) recently participated in a GMP training focused on food safety. The training aligns with the Institute’s pursuit of the Brand Reputation Compliance Global Standard (BRCGS) Certification for Packaging Materials as part of The Global Food Safety Initiative (GFSI). NWI is on schedule to complete this certification in 2024, which will enable it to provide added quality assurance to producers of nonwovens for food-and-beverage-related packaging.

The GMP training was presented by a team of specialists from the NC State Department of Food, Bioprocessing and Nutrition Sciences. Topics covered included Foundations In Food Safety, Pest Control, Food Fraud and Defense, and Document Control.

NWI has been following GMP requirements since 2019, and its most recent audit resulted in a rating of “Excellent” with a score of 962/1000, according to an independent third-party auditor. NWI’s Analytical, Filtration Testing, Spunbond and Hydroentangling, and Meltblown labs are all ISO 9001:2015 accredited.

“Here at NWI we are continuously striving to improve our quality measures,” said Jamie Plummer, lab research specialist. “Over the past several years, we’ve implemented a full suite of standard operating procedures, not only in our labs, but across all our operations. Our goal with BRCGS Packaging Materials Certification is to align our business with GFSI to meet the needs of our current and prospective customers who are serving the food and beverage industry.”

The Nonwovens Institute’s fabrication and testing capabilities include lab-scale systems dedicated to polymer characterization, fiber extrusion and meltblown, with pilot facilities for bicomponent spunbond and meltblown, staple fiber, fiber spinning, needle punching, hydroentangling, thermal bonding and web composite capability. NWI’s analytical and filtration testing facilities offer the ability to analyze and evaluate material performance according to a wide range of industry-specific standard test methods.

- Categories: